Schedule a Call Back

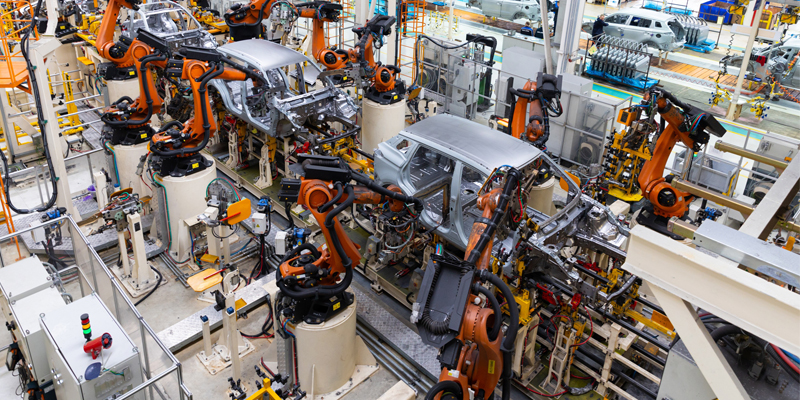

Booming in construction and auto sales driving dies and molds demand in India

Articles

Articles- Jan 29,25

Related Stories

Seco Partners with AMRC to Drive Sustainable Machining through Data Intelligence

Looking ahead, Seco is building toward an AI-powered, automated feedback system that continuously optimises processes in real-time.

Read more

How MNCs are strategising to capture market in India

Today, the Indian MNC scene is changing vastly, with many new ones setting up shop in India. With China becoming less attractive, India is becoming the go to place, writes R Jayaraman and Firoz S Ri..

Read more

Smart Factories in India: Reality or Distant Dream?

As India moves toward its goal of becoming a $7 trillion economy by 2030, embracing smart manufacturing technologies will be crucial for achieving this ambitious target, writes Rakesh Rao. But, is t..

Read moreRelated Products

Angular Head for Vertical Machining Center

Sphoorti Machine Tools Pvt Ltd offers angular head for vertical machining center.

Universal Tapping Machine -model Tr-10/15

Tapping

Machine Tools offers universal tapping machine -model TR-10/15.

Hot Foil Stamping Machine

Friends Engineering Company offers a wide range of hot foil stamping machine.