Schedule a Call Back

A TOTEX approach in water and wastewater infrastructure

Industry News

Industry News- Nov 30,-1

March 2017 – Engineering firms and owner-operators in water and wastewater utilities are constantly looking for better ways to reduce the total cost of infrastructure projects. To meet this end, many are taking a TOTEX (total expenditure) approach to managing and operating their water and wastewater infrastructure assets. As the demand for new infrastructure grows, owner-operators are looking to improve how they manage and mitigate the risk associated with large capital projects. To do this, water and wastewater utilities need to converge the right technology, the right policies and a new, creative method of interaction in order to extend and enhance the life of an asset with asset management at the fore of this strategic process. Connecting IT, OT (operational technology), and ET (engineering technology) is now offering a potential way of reaching this goal.

A key driver enforcing a TOTEX approach in water and wastewater utilities is the lack of complete and accurate engineering information captured during CAPEX that serves as feed for the OPEX cycle. This is important as owner-operators require information from all phases of the project lifecycle to be useful in the asset management or maintenance management systems when the asset reaches handover. In order to improve data quality and accuracy, an emergence of disruptive technologies is helping to deliver the right information to the right teams, at the right time over the entire project lifecycle.

The advent of digital engineering models used during the capital phase of projects have allowed for greater leverage of asset performance modelling, which has provided ways to reduce costs, improve collaboration, and enable asset optimisation for operations. These digital engineering models typically have not had a prominent role in operations as of yet. There is a huge amount of information related to assets that can be leveraged at different phases of a project, such as asset specifications, precise geo-coordination, configuration management, cost information, detailed component information, and recommended maintenance and repair information.

Engineering data is not the only potential for reducing TOTEX. As OT leverages the Industrial Internet of Things (IIoT) with operating systems and sensors to produce huge quantities of data, the need to make this data usable and secure is fast becoming mainstream in its outreach and adoption. So far, OT data has initiated a convergence with IT systems, which has yet to yield significant gains. At Bentley, we see the critical importance of leveraging the engineering data in order to yield significant gains.

Asset management systems that allow a convergence of IT, OT, and ET data will help to bridge the gap between data formats to make infrastructure assets more powerful, efficient, and reliable by exploiting the Big Data potential. Enhanced by the power of the cloud, digital engineering models are evolving toward an upgrade to the IIoT: digital engineering tools that go beyond observing and monitoring the asset’s performance to modelling its desired behaviour to produce better outcomes.

Water and wastewater utilities have been a step ahead of other industries in exploiting the potential for ET and OT data to be better utilised. IIoT and supervisory control and data acquisition (SCADA) software have had a harmonic convergence of their own in enriching the oversight value of data analytics for treatment, distribution, and collection facilities. Engineering departments and the operational control rooms have more reason to interact than ever before, as the common goal of reducing cost and optimising their networks can be realised – in real time. Hydraulic modelling generally has been used for long-term planning, while data from the SCADA systems are used heavily in daily operational decisions. Linking these two technologies has ensured barriers are removed, collaboration has improved, and data is shared for mutually beneficial reasons.

Water and wastewater infrastructure professionals are well-placed to deliver against CAPEX, OPEX, and TOTEX, by keeping continuity and enhancing collaboration through better work processes and an ultimate convergence of IT, OT, and ET. By leveraging digital engineering models, water infrastructure professionals will act as beacons of light for other industries to follow. Its success will be driven by the mutually beneficial nature of TOTEX, with engineers and architects delivering value and creating a new generation of digital natives to act as flag-bearers for infrastructure improvement and asset longevity to the delight of owner-operators.

Related Stories

Entuple E-Mobility Wins National Startup Award for Urban Mobility Excellence

Deep-tech EV powertrain company Entuple E-Mobility has been awarded the National Startup Award by DPIIT for its contributions to urban mobility innovation and sustainability.

Read more

Legrand Inaugurates One of Its Largest Global Manufacturing Facilities in Nashik

Group Legrand India has inaugurated a 30,000 sq m manufacturing facility in Nashik, reinforcing India’s role as a global manufacturing and export hub.

Read more

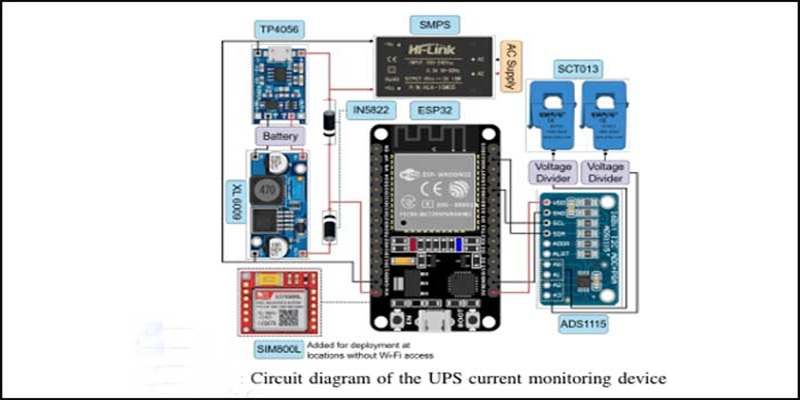

Low-Cost IoT Device Enables Real-Time UPS Monitoring at IIIT-H

Born from a campus IT challenge, IIIT-H researchers have developed Rs 2,000 IoT device that monitors UPS performance during power outages with near-second accuracy.

Read moreRelated Products

Compact Fmc - Motorum 3048tg With Fs2512

Meiban Engineering Technologies Pvt Ltd offers a wide range of Compact FMC - Motorum 3048TG with FS2512.

Structural Adhesive for Solar Panel Roof Mounting

Parson Adhesives India Private Ltd offers a wide range of structural adhesive for solar panel roof mounting – Partite 7535.

Industrial Tsn Switch

Contec launches a future-ready Industrial TSN Switch- SH-9210TSN.