Schedule a Call Back

A rundown of the global battery recycling market

Articles

Articles- Jul 27,24

Related Stories

Carraro India opens first authorised service centre in Faridabad

New Faridabad hub marks Carraro India’s aftermarket expansion, with four centres planned nationwide by 2026.

Read more

Neolite ZKW Commissions New Automotive Lighting Plant in Pune

Neolite ZKW Lightings Limited has commissioned a new manufacturing and design facility in Pune to strengthen automotive lighting capabilities and support OEM customers across vehicle segments.

Read more

Why Batteries Trail Strategy in Humanoid Robot Development

Battery makers are racing ahead of robot OEMs in positioning humanoids as the next growth frontier. This press release examines developments from both perspectives and considers how deeper cross-ind..

Read moreRelated Products

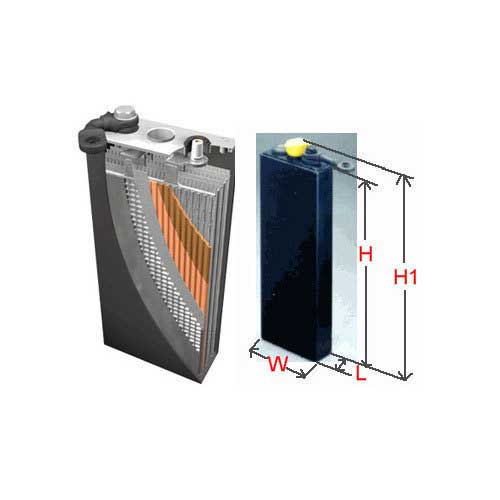

Forklift Battery

Aatous International is a manufacturer and solution provider of a wide range of forklift battery.

Kusam Meco -Wrist Type High Voltage Alarm

‘KUSAM-MECO’ has introduced a new wrist Type High Voltage Alarm Detector - Model KM-HVW-289 having a wide sensing range from 1kV-220 kV AC.

Servotech Power Systems files 2 patents for energy management technologies

Servotech Power Systems, a leading manufacturer of EV chargers and solar solutions, has announced that it has filed two patents for innovative energy management technologies in order to facilitate gri Read more