Schedule a Call Back

Transfluid to present flexible tube machining solutions at Hanover Messe

Industry News

Industry News- Mar 29,17

March 2017 – The increasingly powerful digital connection for tube machining processes is a tailored driver of technical progress within the industry. For hydraulics in particular, solutions are required, which ensure safe tube machining, as well as automated processes where required. Powerful automation is even possible with very low unit quantities, for example with the technical machining of hydraulic connection elements. As such, transfluid – with its axial forming machines of type REB and tool-independent rolling forming with systems of type SRM – offers the solution for hose connections or DKOL connections directly on the tube, for example. These enable sharp-edged contours for sealing elements and optimum surfaces. The production of flanges between 20° and 90° with short clamping lengths can be realised with transfluid forming machines of type UMR – for optimum sealing surfaces and in a single process.

“In the future, greater flexibility will be required for even better processes. I think for example of the online connection between design and our bending software t project. And also of systems that measure both at the building and the finished tube. Such a system must of course be simple to use. That is sure to deliver greater bending freedom,” Stefanie Flaeper, managing director of transfluid, outlines the demands and further developments.

This was the objective of the engineers at transfluid, when they developed their mandrel bending machine of type t bend DB 40220-3A-CNC. With this machine, it is possible to bend thick and thin-walled tubes with diameters in particular from 40 mm and up to 220 mm. The stable design ensures a long service life and simple, rapid tool changes enable diverse applications and improved efficiency.

The right/left-bending machine t bend DB 642 CNC R/L VE with rotating head delivers a strong performance when producing extremely demanding geometries, even when structural obstacles are present. With this servo-electrically driven concept for tube diameters up to 42 mm, each bending head has two tool levels as standard. Process assurance is provided by the complete visualisation of production processes on the freely programmable CNC touch panel control.

transfluid offers flexibility together with simple and effective technology for bending directly on site in the building, with its latest generation of the mobile bending machine t bend MB 642. With it, hydraulic lines can be laid at the installation site. As additional equipment, you can also chose from the internal and external deburrer, a saw, an assembly device for all conventional connection systems (flanging and cutting ring fittings), as well as metal circular saws.

The experts in tube processing machines will be presenting their diverse solutions for tubes at the Hanover trade fair 2017, in Hall 20 at Stand B14.

Related Stories

Transfluid to present flexible tube machining solutions at Hanover Messe

The increasingly powerful digital connection for tube machining processes is a tailored driver of technical progress within the industry.

Read moreRelated Products

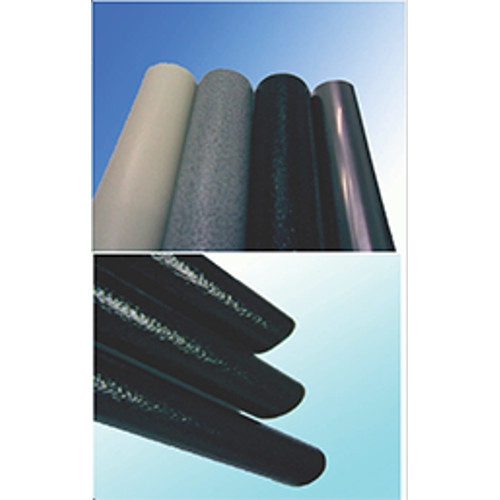

Anti Spatter Tube

IBK Engineers Pvt Ltd offers a wide range of anti spatter

tube.

Togawa Paint Hoses

Pneumec Kontrolls offers a wide range of Togawa paint hoses.

S Simplex Pipes and S Eco Esd Pipe

Concord United Products offers S Simplex Pipes And S Eco Esd Pipe.