Schedule a Call Back

SEW Eurodrive: Producing the gears that drive the world

Technical Articles

Technical Articles- Jan 01,18

Related Stories

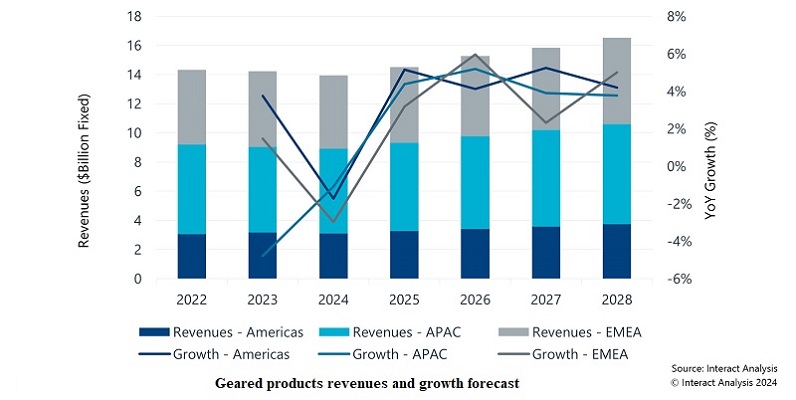

Global geared products market anticipates slowdown; India to prop up revenue

Interact Analysis forecasts a revenue decline of 1.9 per cent for the global geared motors and industrial gears market in 2024. It is expected that Indian and Southeast Asian markets will prop up re..

Read more

ANCA to focus on high-end CNC machines

ANCA will showcase a range of technologically innovative manufacturing and engineering products and applications at IMTEX 2023.

Read more

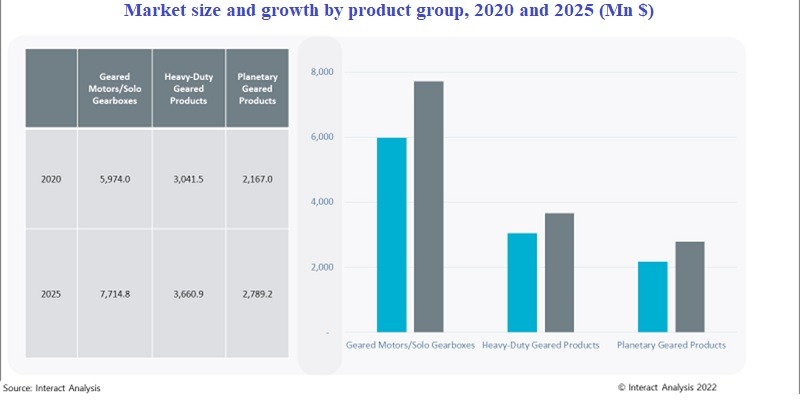

Geared products market to reach $14 bn by 2025: Report

While China continues to be the largest market for industrial geared products, SEW Eurodrive retain the largest share of the market, says Interact Analysis report

Read moreRelated Products

Cluster Gears

Trishla

Gear Industries is engaged in manufacture and supply of a wide range of cluster

gears.

Ground Spiral Bevel Gear

Bevel Gears (India) Pvt Ltd offers a wide range of ground spiral bevel gear.

Bearings

ARB Bearings is a manufacturer of a wide variety of bearings. Read more