Schedule a Call Back

Objectify Technologies participates in Formnext 2019, showcases AM solutions

Industry News

Industry News- Nov 20,19

Delhi

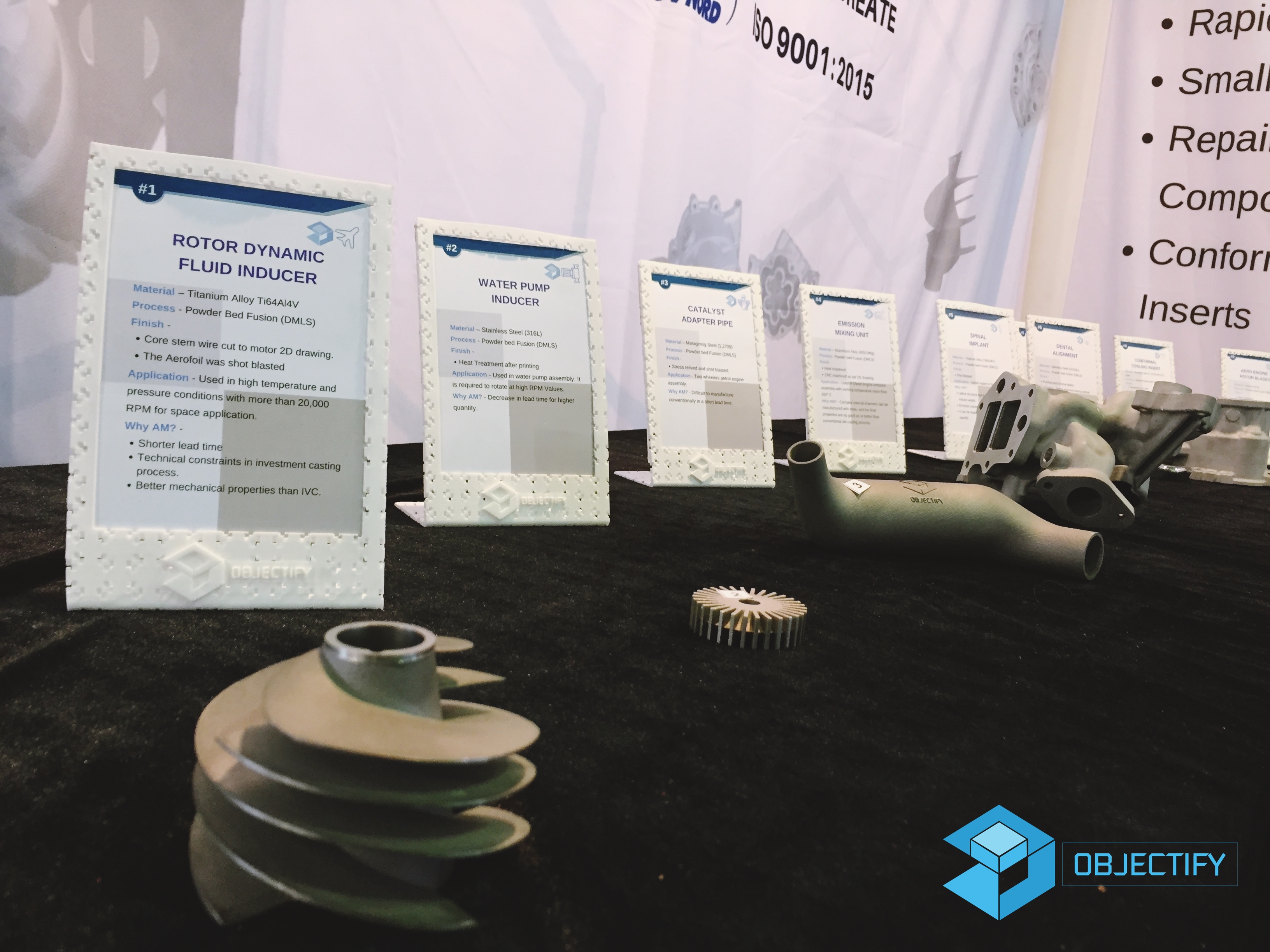

Objectify Technnologies, one of the leading additive manufacturing solution provider with its commitment to the European market has participated at the Formnext 2019 expo and showcased their AM solutions between November 19 and 22 at Frankfurt, Germany.

The event was an ideal platform for companies and professionals seeking to learn new developments in additive manufacturing (AM), explore business opportunities in the European market and meet industry professionals.

Arpit Sahu, Director, Objectify Technologies, said, “3D printing is ever-evolving field and at Formnext our aim was to meet as many AM professionals and discuss challenges, technical developments, and possibilities in the 3D printing space. We learned from the global community of 3D printing about the opportunities and demand in specific European countries and shared our knowledge and experience about building highly critical parts and dealing with global giants from India.”

With relentless quality measurements and standardisation, Objectify has acquired certificates such as AS9100 Rev Dand ISO 9001:2015 by TUV Nord. The company is capable of both metal & polymer AM technologies and has served more than 500 customers from over 10 different sectors.

The company’s infrastructure includes DMLS (Direct Metal Laser Sintering), SLS (Selective Laser Sintering), SLA (Stereolithography Apparatus), VC (Vacuum Casting), CNC Machining and other post-processing technologies. Objectify majorly caters to industries such as aerospace, automotive,oil & gas, space, tooling, heavy engineering, and consumer goods, among others.

“Since our inception, we have always strived to become better and continuously upgrade our technical know-how. This has resulted in gaining confidence in some of the large companies in India and we have successfully become an import substitute for some global engineering companies. However, we see bigger opportunities in the European market for AM with Germany being one of the leading countries to develop and adopt 3D printing technologies,” added Arpit.

Delhi

Objectify Technnologies, one of the leading additive manufacturing solution provider with its commitment to the European market has participated at the Formnext 2019 expo and showcased their AM solutions between November 19 and 22 at Frankfurt, Germany.

The event was an ideal platform for companies and professionals seeking to learn new developments in additive manufacturing (AM), explore business opportunities in the European market and meet industry professionals.

Arpit Sahu, Director, Objectify Technologies, said, “3D printing is ever-evolving field and at Formnext our aim was to meet as many AM professionals and discuss challenges, technical developments, and possibilities in the 3D printing space. We learned from the global community of 3D printing about the opportunities and demand in specific European countries and shared our knowledge and experience about building highly critical parts and dealing with global giants from India.”

With relentless quality measurements and standardisation, Objectify has acquired certificates such as AS9100 Rev Dand ISO 9001:2015 by TUV Nord. The company is capable of both metal & polymer AM technologies and has served more than 500 customers from over 10 different sectors.

The company’s infrastructure includes DMLS (Direct Metal Laser Sintering), SLS (Selective Laser Sintering), SLA (Stereolithography Apparatus), VC (Vacuum Casting), CNC Machining and other post-processing technologies. Objectify majorly caters to industries such as aerospace, automotive,oil & gas, space, tooling, heavy engineering, and consumer goods, among others.

“Since our inception, we have always strived to become better and continuously upgrade our technical know-how. This has resulted in gaining confidence in some of the large companies in India and we have successfully become an import substitute for some global engineering companies. However, we see bigger opportunities in the European market for AM with Germany being one of the leading countries to develop and adopt 3D printing technologies,” added Arpit.

Related Stories

3D Printing Strengthens the Foundations of Smart Manufacturing

The global 3D printing market was estimated at $30.55 billion in 2025 and is projected to reach $168.93 billion by 2033, growing at a compound annual growth rate of 23.9 per cent from 2026 to 2033.

Read more

Phillips Opens Expertise Centre in Pune to Boost Manufacturing Innovation

New Chakan facility to promote advanced, smart and sustainable manufacturing

Read more

Rare crystal shapes yield stronger 3D-printed metal parts

Quasicrystals, which were previously considered a myth, are now replicable for large-scale industrial applications. Stakeholders must support investments in 3D printing technologies and continued re..

Read moreRelated Products

Automatic Food Snacks Packaging Machine

Grace Food Processing & Packaging Machinery offers

automatic food snacks packaging machine.

Servo Auger Machine

All India Packing Machines offers collar type servo auger machine. Read more

Shrink Tunnel

Vista Technopack Machines offers a range of online shrink tunnel with L sealers. Read more