Schedule a Call Back

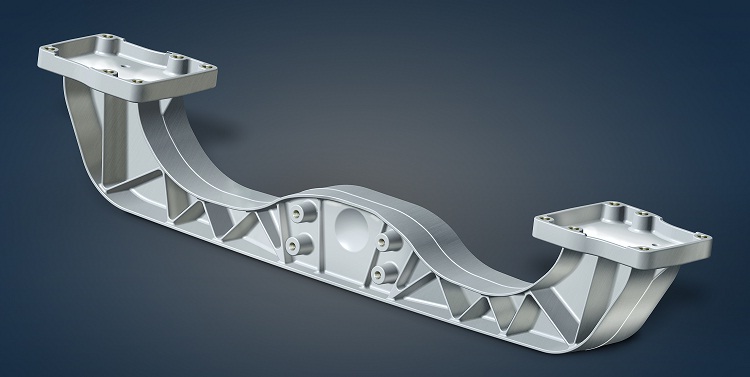

Jaya Hind Industries produces complex aluminium structural parts for automaker

Industry News

Industry News- Aug 06,19

Related Stories

Setco Automotive enters engine cooling market with new water pump launch

Setco Automotive expands its product range with a new water pump for LCVs and MHCVs, reinforcing its presence beyond clutches into engine cooling solutions for global OEM and aftermarket clients.

Read more

Can India’s Exports Takeoff Amid Global Market Uncertainty?

India's merchandise exports are navigating a complex global landscape marked by economic and geopolitical turbulence, including trade wars. India needs to take multiple measures to build a resilient..

Read more

Low-emission brake disk: Best practice in data-driven production

Eurozone's decision to equip new car models with low-emission braking systems from next year represents a technological leap for the manufacturing industry

Read moreRelated Products

Tata Motors unveils facilities for development of Hydrogen propulsion tech

Tata Motors, India?s largest automobile company, unveiled two state-of-the-art & new-age R&D facilities for meeting its mission of offering sustainable mobility solutions. The unveilings constitute of Read more

Tata Motors plans petrol powertrain for Harrier and Safari SUVs

Tata Motors is in the process of developing a new petrol powertrain for its premium sports utility vehicles, the Harrier and Safari, as confirmed by a senior company official. Currently, these models Read more

Electric Vehicle Charger

RRT Electro is engaged in manufacturing of customized Power Electronic Products over two decades having capability to Design, Develop, Prototyping, Regulatory Compliance testing & Certification, Manuf Read more