Schedule a Call Back

ISRO selects Hind High Vacuum for supplying thin film metallised circuit

Industry News

Industry News- Sep 24,18

Related Stories

Minda Corp, Toyodenso Form JV for Automotive Switches

The joint venture will set up a greenfield facility in Noida (Uttar Pradesh) with operations expected to commence in the second half of FY 2026–27

Read more

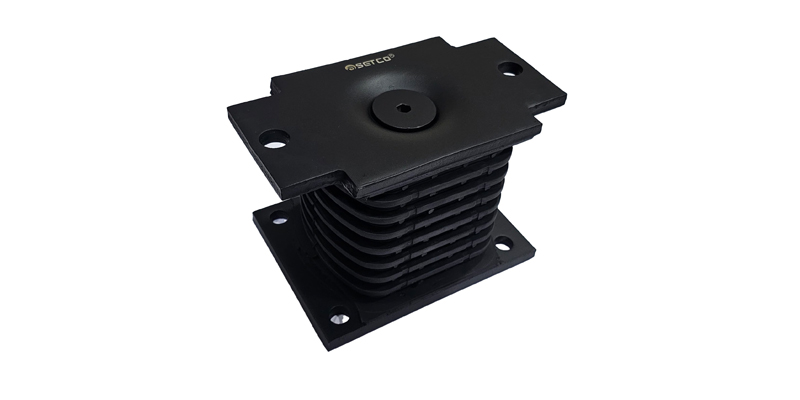

Setco Automotive launches load cushion and torque rod bush

Designed to perform in challenging conditions, these suspension components are engineered to enhance vehicle stability, ride quality, and shock absorption.

Read more

We see strong demand for process equipment in next 5 years: Shalabh Singh

in this exclusive conversation with Rakesh Rao, Shalabh Singh, Chief of Business Development at Isgec Heavy Engineering Ltd, delves into how Isgec is aligning itself with national priorities while t..

Read moreRelated Products

Plated Through Holes

Anand Electronic Circuits offers a wide range of Plated Through Holes. This circuits are printed and integrated.

Read more

Printed Circuit Boards

Anand Electronic Circuits offers a wide range of Printed Circuit Boards. They offer a wide range of Printed Circuit Board used to support electrically connect electronic components. Made Read more

Aluminum Metal Core PCB

Acme Circuits offers a wide range of Aluminum Metal Core PCB.

Read more