Schedule a Call Back

GE Additive acquires GeonX to strengthen software simulation capabilities

Industry News

Industry News- Nov 17,17

Related Stories

AuraML Launches India’s First Multimodal World Simulation Model

AuraML unveils AuraSim, a multimodal world simulation platform powered by NVIDIA, enabling physics-ready digital twins for robotics and physical AI development.

Read more

Tata Technologies posts steady Q3 FY26 growth, signals margin rebound in Q4

Tata Technologies reported QoQ revenue growth in Q3 FY26 and expects over 10 per cent sequential growth with margin recovery in Q4.

Read more

Virtusa Acquires SmartSoC to Enter High-Growth Semiconductor Engineering

Virtusa has acquired Bengaluru-based SmartSoC Solutions, expanding into semiconductor engineering and strengthening its end-to-end digital services from silicon to cloud and applications.

Read moreRelated Products

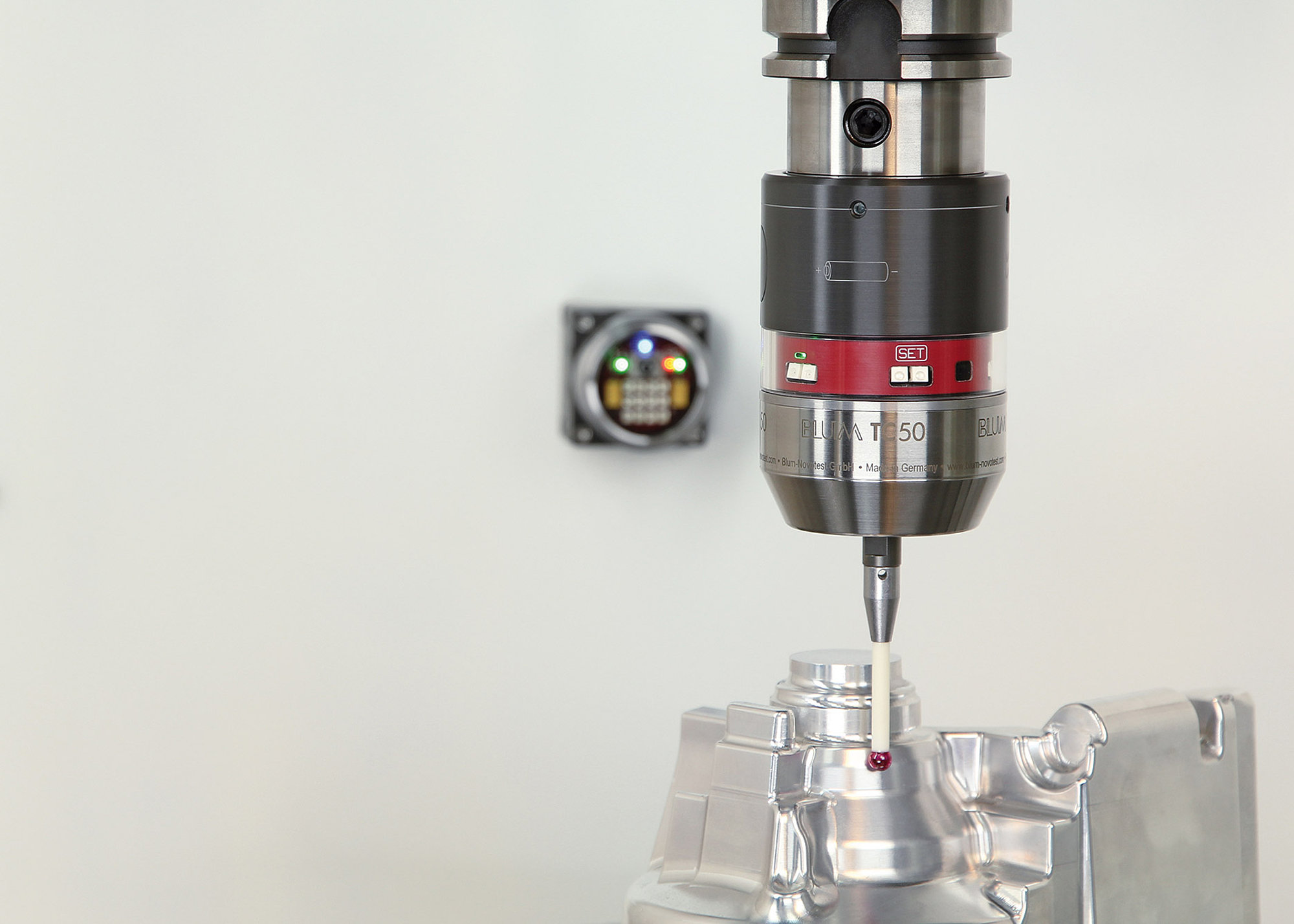

Measurement Software

Blum-Novotest Measuring & Testing Technology Pvt Ltd offers a wide range of measurement software.

Twincat Controller Redundancy Software

Beckhoff Automation offers TwinCAT Controller Redundancy – the software-based solution protects plant uptime through redundant control operation.

Software System

Beckhoff’s TwinCAT CNC offers the option to implement interpolation with up to 32 simultaneously interpolating axes.

Read more