Schedule a Call Back

Elgi compressors help industries in saving significant energy: Dr Jairam Varadaraj

Interviews

Interviews- May 19,20

In this interview with Rakesh Rao, Dr Jairam Varadaraj, MD, Elgi Equipments, elaborates on the dynamics of compressors market and why it is necessary for companies to recalibrate and reorient their business strategies amid COVID 19 challenge.

Air compressors find usage across wide range of

industries. Coimbatore headquartered Elgi Equipments

today is a well-known global compressor brand operating in the most competitive

and advanced markets of the world. In conversation with Rakesh Rao, Dr Jairam

Varadaraj, Managing Director, Elgi Equipments,

elaborates on the growth journey of the company and qualities required to be a

force to reckon with on the global landscape.

Elgi today is one of the leading global

players in air compressors market. How would you describe this journey?

Our journey really started with the opening up of

the Indian economy in the early 90s when the licensing system was dismantled

and India was integrated into the rest of the world. At that moment we

realised that there is a huge opportunity for us globally. On the other hand, we

knew, if we are not a globally relevant player, we will not be alive even in

the Indian market because most of our competitors were multinational, global

players.

So, we had to be, at the very least, as good as

them if not better. That is when our journey started. If you look at any

business, the global opportunities are exponentially higher than the Indian

opportunity and that made a lot of sense for us too. But to take India-focus

business and to transform it to be a globally centric business and organisation,

it is a very long process, especially in manufacturing of capital equipment. We

had to lay a lot of focus on fundamentals - like technology, product

development, manufacturing systems, human development, etc. All this took

a long time because these were transformational changes.

Credible growth in the international markets has

been really in the last 8-10 years, when we have been able to establish our

capability in all the difficult markets like Europe, the US and Australia. This

is the journey that we will continue to pursue for the organisation.

During your rise on the global

landscape, what challenges did you faced? How did you overcome these hurdles?

When we started our journey, we knew we need to lay

the foundation for the right to play - that means getting your technology

levels up to a point where you have the knowledge of not just the know-how, but

also the know why of the technology.

To do that takes time and a lot of

partnership. We also made a lot of mistakes along the way and you need to

build enough stamina within the organisation to withstand these failures and learn

from them. Technology was a very big foundation challenge, as we wanted to

build it on our own and not take the licensing route (which would have

restricted our growth). We needed to build it bricks by bricks by partnering

with various organisations and universities from all over the world.

The second challenge was quality to compete in

markets globally. For an unknown and Made in India brand failure is just not

acceptable. So, it is not about making products of very high standards but

making them better than the best. Bringing in quality-consciousness among

people and implementing processes to make products of high-quality standards

was another big transformational change that we had to adopt to.

Finally, it is about strategy; you cannot be a

global player by being everything for everybody. One has to make some very

deliberate choices in which products and markets you want to focus on.

It has been a learning journey; we made some

mistakes and learned from it and made changes accordingly. Today, we are

firmly in control of these three dimensions and we are moving along nicely.

How is the market for air compressors in

India?

India represents close to about 5-6 per cent of the

global market. Compressed air is a utility and the air compressor provides that

utility. Like a generator generates electricity and electricity is a utility.

Every manufacturing company needs compressed air

and, therefore, compressor. It is a good thing in our business because we

are not dependent on any one industry as a big contributor for our business and,

therefore, the risks are low. I cannot think of even one industry that contributes

more than maybe 3-4 percent to our revenue.

What

do you bring to the table for your customers?

The biggest life cycle cost in a compressor is

energy consumption; close to 75 percent of the life cycle cost of a compressor

is energy. Compressed air itself is not a very efficient source of energy, though

it has got a lot of other virtues like safe & easy to transport, easy to

use, etc but it has got inefficiency. So, our value proposition to our

customers is we bring best efficiencies in the world and, therefore, when they

buy our compressors, the savings are pretty significant.

Second dimension of life cycle cost is the

maintenance cost and our compressors have the lowest maintenance cost in the

world. When we combine these two, the customer’s value proposition very

high.

According

to you (a person who has travelled across the world), what are the strengths

and weaknesses of Indian entrepreneurs?

An Indian entrepreneur is an extremely resilient

person. When you operate in India, you operate under extremely tough

conditions - lots of restrictions, lack of resources, inadequate infrastructure

(compared to rest of the world), etc - so you have to concentrate on the

fundamentals of your business. You also need to manage the environment and

there is so much of distraction there. By virtue of all these, an Indian

entrepreneur has become very resilient. If this resilient entrepreneur gets

an environment that takes care of itself and supports him/her, your ability to

produce results is phenomenally more. So that's on the positive side.

On the negative side, we have been inward looking

country right from our independence. Because of our inward-looking mindset

and psyche, we always look at as India out opportunity rather than a global in

opportunity. This is a weakness. We need to make a mental shift whereby

we look at the world as an opportunity and, also, sell in India rather than

make for India and then look to sell outside.

What kind of new opportunities are

you exploring globally as well as in India?

We are steadfast in our commitment to remain in the

compressibility. The compressor business has got a very wide saddle and even

though we play in close to 80 per cent of the space, there are always opportunity

for improvements and expansion. We are constantly looking to expand portfolio

to give our customers a complete solution. This is an ongoing process.

On the technology front, we are looking at creating

breakthrough products, the opportunity for which exists.

How

are you recalibrating your growth plans after Covid 19 pandemic?

We continue to be even more committed to our goal

called CK2 or 'Conquer K2' - K2 being the second tallest peak in the world - that

is to be number two in the world.

There are two critical dimensions to this crisis. First,

we need to understand what is the bottom of this curve. Second, how long will

it take to recover from this bottom. These two dimensions are critical for us

to calibrate as accurately as possible. The situation is very uncertain;

hence it is very difficult to put an exact number on it.

So, you have to work with multiple scenarios and

create financial stamina inside the organisation to be able to withstand

whichever scenario comes in. Looking at the present situation, all companies

across the world will witness a pretty large percentage drop in business. There

may be some exceptions like pharmaceuticals, food, essential goods, FMCG, etc

who will continue to sustain at a reasonably good level, but most other

businesses would hit a deep bottom. Now when you hit a deep bottom, then the

current business model (that you have been running for all these years) is no

longer relevant. The situation is so grave that you need to go back and revisit

your fundamental assumptions of your business model and recalibrate, reorient

and redirect it.

Related Stories

Ingersoll Rand Launches LS Series Oil-free low-pressure Compressors in India

Ingersoll Rand India has introduced its LS Series low-pressure oil-free screw air compressors, delivering ISO Class 0 air with high efficiency for demanding industrial applications.

Read more

Atlas Copco launches X-Air+ 750-20 portable compressor India

Atlas Copco has launched the X-Air+ 750-20 portable air compressor in India, targeting water well drilling and mining needs with silent operation, fuel efficiency, mobility and monitoring features.

Read more

MAHLE India to double business in 4–6 years: Milind Godbole

MAHLE India to double business in 4–6 years: Milind Godbole

Read moreRelated Products

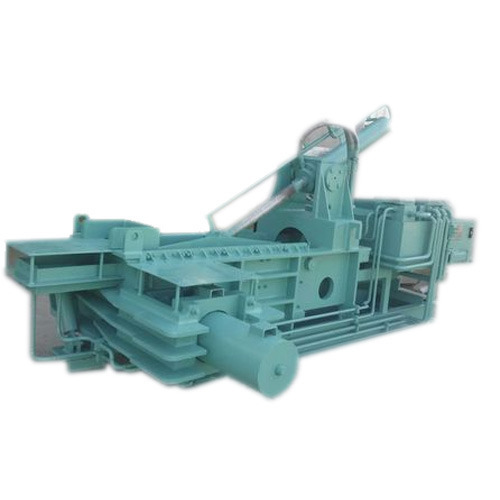

Baling Machine

Mask Hydraulic Machineries provide triple action scrap baling machines. Read more

Manifold Block

Om Shakthi Hydraulics offers a wide range of hydraulic manifold blocks. Read more

Exclusive Hydraulic Fittings

Supreme Engineers is engaged in manufacturing and supplying an exclusive range of hydraulic fittings. Read more