Schedule a Call Back

Aspen Technology introduces aspenONE Version 11 Software

Industry News

Industry News- Apr 12,19

Related Stories

ARC’s 23rd India Forum: Winning in the Industrial AI Era

ARC’s 23rd India Forum, Winning in the Industrial AI Era, G Ganapathiraman, ARC Advisory Group, Industrial AI, Smart Manufacturing, Digital Transformation, AI in Industry 4.0, Predictive Maintenan..

Read more

Deploying industrial AI with sustainability

Industrial AI stems from combining AI with models, based on engineering fundamentals with crucial domain-expertise driven guardrails around AI applications. Results follow the scientific laws i.e., ..

Read more

Aspen Technology introduces new software updates, enables advanced levels of operational excellence

Company shares new aspenONE updates to help customers more quickly develop and implement reliable, impactful sustainability solutions.

Read moreRelated Products

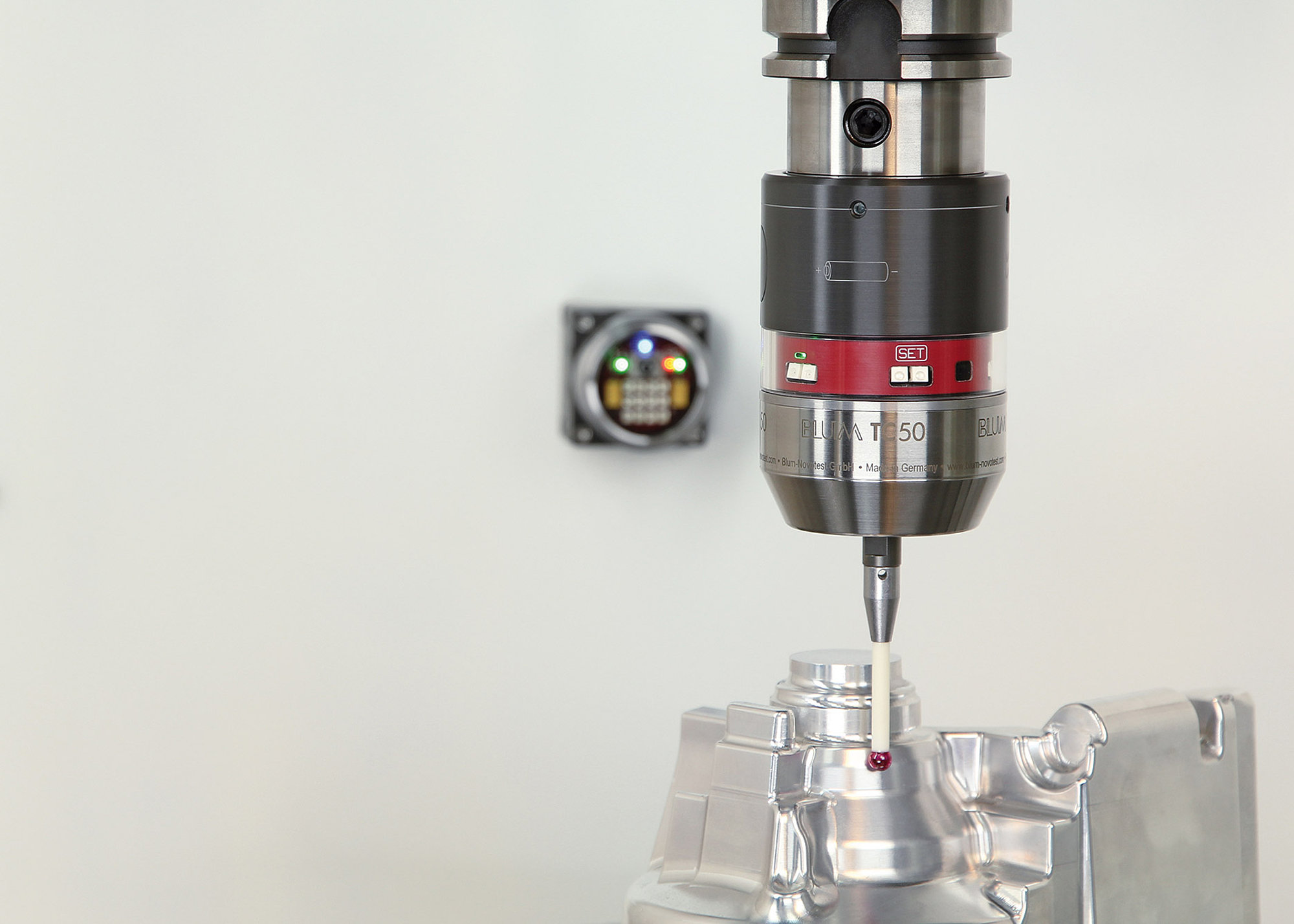

Measurement Software

Blum-Novotest Measuring & Testing Technology Pvt Ltd offers a wide range of measurement software.

Twincat Controller Redundancy Software

Beckhoff Automation offers TwinCAT Controller Redundancy – the software-based solution protects plant uptime through redundant control operation.

Software System

Beckhoff’s TwinCAT CNC offers the option to implement interpolation with up to 32 simultaneously interpolating axes.

Read more