Schedule a Call Back

Why Workplace Safety is Crucial for the Success of Make in India

Articles

Articles- Jan 26,26

Key Takeaways:

- India’s manufacturing growth under Make in India and PLI is accelerating, but inadequate workplace safety practices and weak implementation of Labour Codes continue to put workers and the sector’s credibility at risk.

- The article stresses that leadership-driven safety culture, continuous training, and regular audits are critical to reducing accidents, protecting worker health, and ensuring long-term, sustainable manufacturing growth.

India is at a critical juncture in its manufacturing journey. According to experts, the manufacturing sector currently contributes about 17 per cent to India’s GDP and is expected to rise to 25 per cent by 2047. Initiatives such as Make in India and the Production Linked Incentive (PLI) scheme have firmly positioned India on the global supply chain map. As global companies adapt their strategies, India has a unique opportunity to strengthen its position as a manufacturing hub this decade.

However, as more industries scale up and job creation accelerates, protecting workers in the sector becomes a pressing issue. While India's Labour Codes represent a significant change aimed at balancing employee welfare with ease of doing business, their effectiveness depends on cooperation among stakeholders and strong implementation.

Currently, many manufacturing units in India still struggle to implement workplace safety practices. Data from the Ministry of Labour and Employment’s Directorate General of Factory Advice Service and Labour Institutes (DGFASLI) in 2022 indicated that, on average, three workers lose their lives and eleven sustain injuries daily in registered factories.

Industrial accidents in India have caused significant loss of life and serious injuries over time. For these reasons, industry stakeholders must place greater emphasis on safety measures to help prevent adverse incidents. Addressing safety deficiencies is vital for the sector’s reputation and sustainable growth. Emphasising occupational health and safety is essential to building trust among industry professionals and ensuring long-term success for Make-in-India.

How can the manufacturing sector improve workplace safety?

Many workers, especially in small and unorganised sectors, lack proper training, partly due to high turnover and employers' reluctance to invest in safety. Building a safety culture with committed leadership can encourage better training and safer conditions. Without these practices, workers face increased risks of injury and death.

In addition to physical risks, manufacturing workers face significant health hazards. Employees in these environments may experience long-term health concerns, such as musculoskeletal disorders from repetitive manual tasks and respiratory diseases, including silicosis, from exposure to dust. Chronic conditions associated with inadequate workplace safety measures can also arise. The combination of such health risks and the potential for workplace accidents may lead to serious long-term consequences for both the workforce and the organisation.

A safe workplace goes beyond providing equipment or maintaining machinery — it requires a culture where safety is a top priority. Leaders must support protection initiatives and communicate their importance, while regular meetings, feedback, and safety audits should be standard practice. Encouraging staff to report hazards and get involved in safety programmes fosters responsibility.

Behaviour-based approaches, which monitor worker habits to prevent accidents, help reduce incidents and promote personal accountability. Regular safety audits identify risks and assess the effectiveness of measures, ensure protocols are followed, and highlight areas for improvement.

Comprehensive programmes require on-going training, adherence to procedures, adaptability to industry changes, and inclusivity for both physical and psychological well-being. Employees need to feel safe when voicing concerns.

Continuous improvement is essential; organisations should update protocols as new technologies and risks arise, embracing innovation not only in operations but also in safety practices.

Workplace safety will enable Make-in-India’s long-term sustainability

Workplace accidents can result in significant financial and operational impacts, such as increased healthcare expenditures, legal costs, reduced productivity, and reputational damage. Employee injuries may also negatively affect morale and disrupt normal business processes.

Conversely, organisations that prioritise safety typically observe enhanced productivity, as employees who feel protected are more focused, engaged, and motivated. Furthermore, cultivating a positive safety culture contributes to a more appealing work environment, facilitating the recruitment of highly qualified talent.

Effective safety management promotes long-term business sustainability. When employees receive comprehensive training in management protocols and are encouraged to report hazards, organisations experience fewer costly incidents. Businesses that emphasise employee protection also mitigate the risks of legal action and compliance penalties.

Workplace safety is essential for India's manufacturing sector as it strives for global leadership under the Make-in-India initiative. As industrial growth accelerates, safety measures must keep pace. Companies can safeguard employees, boost productivity, and strengthen their reputation by prioritising responsible and compliant practices.

About the author:

Suresh Tanwar is the Senior Head of Audit and Consultancy at British Safety Council, India. He is a seasoned safety professional and strategist with decades of experience in Safety, Health, and Environment (SH&E). An active member of the CII National Safety Task Force Committee since its inception, Tanwar has played a significant role in shaping safety policies and best practices. Before joining British Safety Council, India, he served as Chief - Group Safety & Health for the Tata Group of Companies.

Related Stories

Indian manufacturing sector: Negotiating its way in a less VUCA world

India’s manufacturing sector is evolving through policy support, technology adoption and sectoral growth, though challenges in R&D and skilling remain, writes Prof R Jayaraman, Head, Capstone Proj..

Read more

Manufacturing Strength Behind India’s Self-reliance and Global Positioning

India’s manufacturing sector is evolving from domestic self-reliance to global leadership, navigating a VUCA environment through strategic policy, capability building and infrastructure-led execut..

Read more

India’s Manufacturing Reset in an Uncertain World

Global manufacturing is being reshaped by volatility and disruption. This release outlines how India is strengthening depth, resilience and capability to emerge as a long-term manufacturing partner,..

Read moreRelated Products

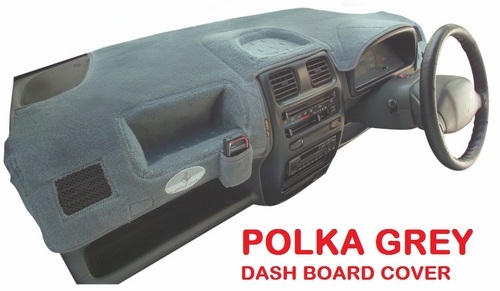

Grey Polka Dash Board Covers

Elegant Auto Accessories offers a wide range of grey polka dash board covers.

Fire Protection - Industrial Sirens

Amit Safety Enterprises offers a wide range of fire protection industrial sirens.

Read more

Fire Alarm Sysytem

Nayakson Security Systems is offering a range of fire alarm, intrusion alarm and gas alarm systems.