Schedule a Call Back

Integrating Industry 4.0 and digitalisation in manufacturing

Articles

Articles- Nov 23,24

Similarly the data for the work orders, issued raw materials, recipe masters, can originate from the ERP. The batching system can then take this information automatically from the ERP, removing the need for human interference, opines, Ramkumar R S, Director, Autosys and Koremec Group of Companies.

The Indian manufacturing sector has been modernising at a rapid pace over the last 2 decades. Digital transformation in information technology (IT) and process automation / operational technologies (OT), in factories, have seen widespread investments and have now reached mainstream adoption, including among MSMEs.

Industry 4.0, aims to take this journey further, converging and bridging both IT and OT; amplifying the benefits of both these technologies tenfold.

Refractory industry as an example

Refractory manufacturing is only used as an example in the article, as it has both, batch processes involving bulk materials and discrete processes that go through multiple stages. A similar Industry 4.0 implementation can be considered for any industry. By adding Industry 4.0 to existing automation investments, any industry can amplify the benefits of these technologies manyfold.

Application of Industry 4.0 in manufacturing can be broadly classified into three major areas:

- Industry 4.0 enabled batching process (for bulk materials)

- Industry 4.0 enabled digitalisation of discrete processes (inspection, stacking, movement, traceability etc.)

- Real time monitoring of one or more plants from head office

- Industry 4.0 enabled batching automation (for bulk materials)

A batching plant is a plant, where multiple raw materials (or multiples grades of the same raw material) are weighed and mixed in a specific proportion as defined by a recipe.

A typical automated batching plant may have silo-based architecture (where raw materials are stored in large silos), or it could have silo-less architecture, (where the raw materials are automatically taken from big-bags).

The raw materials are fed through electronically controlled variable speed feeders into a weigh hopper and the weighed materials are automatically transported to the mixer.

A typical recipe would have major materials in tons, minor materials in kilograms and micro additives in grams. Different materials will have different flow characteristics. Automating this process requires in-depth expertise in feeder design and system design.

How to make a batching system – Industry 4.0 enabled?

Stores to raw material loading to batching integration: The raw material issued, from stores to production need to be digitised with barcodes / RFIDs. The issued raw material bags must be traced till they are loaded on to the batching silos / bag holders. This is to ensure that the raw material to batch traceability and digital visibility process of all material movements perform smoothly on the shop floor. This also ensures Poka-Yoke. An incorrect material would never get loaded onto the wrong silo / bag holder, as the concerned system / gate would refuse to open, if the scanned code does not match.

Raw material to batch traceability: The store issued data flows into the batching system. So every batch mix and its contents can be digitally traced to the raw material bags issued from the stores and from there to the supplier who supplied them.

Mixer batch output traceability: By implementing RFID based bins, the output from each mixer batch can be traced to further downstream processes, such as bagging or press.

Live ERP updating: The data of the raw material consumption, number of work orders completed, the WIP stock, the amount of semi-finished and finished goods stock –will flow back from the batching system into the ERP. There will be no need to reconcile batching system reports with ERP system data. There is no need to manually update the ERP system at the end of each day, as the correct information is automatically updated after every batch, and the ERP system will reflect the correct data status at all times.

Similarly the data for the work orders, issued raw materials, recipe masters, can originate from the ERP. The batching system can then take this information automatically from the ERP, removing the need for human interference. The output tonnage from the mixer (product wise) and the input tonnage from raw material stores can be reconciled and tallied automatically and accurately.

Energy monitoring: The batching system can also be made to measure and monitor the energy consumption of various equipments – from raw material handling systems to feeders, mixers and presses. This can be correlated to each batch and each product.

High level reporting: Instead of low level batch number wise reports, the system will be able to generate high level reports such as product wise and work order wise production, product wise and work order wise energy consumption, stock position of all the raw materials, WIPs, SFGs and FGs.

Industry 4.0 enabled digitalisation of discrete processes

Robotic stacking: Picking up discrete items and stacking / unstacking them on the trolley that will eventually go for the next process is automated using automatic pick and place robots.

WIP traceability: A combination of barcode applicators and RFID tags are used to trace the flow of material from the output of one process to another. A digitally aware system that tracks the ‘Sequence of input / output’ into and out of a process is necessary for unbroken traceability. This ensures low cost; low temperature bar codes and ID tags can be used.

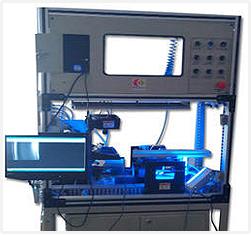

Digital inspection integrated with robotic stackers: Digital inspection technologies can ensure that each and every piece is inspected accurately for defects, instead of a sample-based approach or depending on human inspectors. These systems can be integrated with robotic stackers, so that the pieces are inspected and passed before they are stacked (or rejected if necessary).

Laser based dimension measurement systems can check for deviation in the geometry of each piece.

A weighing scale can check for deviation in the weight of each piece.

An advanced camera based system can check for deviation in surface quality.

Some sample pieces of each batch can also be subjected to an automated ‘Hit and listen’ audio test, where the audio is recorded for future analysis.

Heating process traceability: The heating profile / temperature data can be stored historically with date / time, so that the process traceability can be achieved. This is done by linking the identity of the product / trolley, and its in-out times with the corresponding process parameters during the same time.

Finished goods traceability: While automatic bagging machines, robotic stackers and palletisers are deployed, it is important to link the final finished good identity (serial no, batch no, invoice no, customer ID etc) and map it back to the internal barcodes and RFID tags used during the production process.

These traceability data will be held in a separate database for future reporting and analysis.

Real time monitoring of one or more plants from the headquarters

While each plant has its own automation and traceability systems, we can integrate these systems from one or more plants to the head office. All the KPIs of the plants can be monitored centrally from the head office, in real time.

This is done through a combination of plant level data aggregators to pull data from individual PLC systems, plant level firewall and VPN systems, intermediate secure cloud accounts to pool in data from multiple plants and finally IT Infrastructure at the head office to consolidate and visualise the data in the form of real time dashboards.

Conclusion

Refractory manufacturing, as an industry, is only an example. A similar Industry 4.0 implementation can be considered for any industry. By adding Industry 4.0 to existing automation investments, the industry can amplify the benefits of these technologies manyfold.

Some of the benefits include:

- Improved quality and yield, reduced losses.

- Enhanced material traceability and process traceability.

- Instant and live visibility of all critical production data and KPIs across plants.

—-----------------------------------------------------------------------------------------------------

About the author:

Ramkumar R S is the Marketing Director at Autosys Engineering, which provides outsourced on demand manufacturing services to OEMs and large EPC companies in areas such as mechanical, material handling, electrical, control and instrumentation. Autosys and Koremec Group of companies have been working across a wide variety of industry verticals in the areas of batching automation, discrete automation, PLC/SCADA, traceability, MES, Industry 4.0, ERP integration, mobile apps and so on.

Related Stories

Integrating Industry 4.0 and digitalisation in manufacturing

Refractory manufacturing is only used as an example in the article, as it has both, batch processes involving bulk materials and discrete processes that go through multiple stages.

Read more

Automatic storage and retrieval

Many might assume that Automated Storage and Retrieval Systems (ASRS) are exclusively used in warehouses and stores. However, Autosys has innovatively expanded the application of ASRS beyond these t..

Read more

Autosys: An expert you can rely on

Autosys and its leadership team has over 30 years of experience across 500+ projects in a wide variety of sectors and industries.

Read moreRelated Products

Fire Alarm

Safe Zone is prominent traders and suppliers of the industry, offering a wide range of wireless fire alarm.

Read more

Sorting Automation Systems

Renovus Vision Automation offers sorting automation systems.

Read more

Manual Bagging System

Alligator

Automations provides a wide range of manual bagging systems.