Schedule a Call Back

Accenture and Schaeffler pave the way for industrial humanoid robots

Industry News

Industry News- Apr 01,25

At Hannover Messe

2025, the companies show how to optimise various work scenarios, from

human-centric to human/robot collaboration and full automation, with the latest

simulation, AI and data technologies from NVIDIA and Microsoft. These scenarios

include industrial automation systems, autonomous mobile robots (AMRs), Schaeffler’s mobile manipulator

cobot EMMA, and general-purpose humanoid robots such as Agility

Robotics’ Digit and Sanctuary AI’s Phoenix.

“As a leading

motion technology company, Schaeffler leverages disruptive innovations such as

physical AI, digital twins, and humanoid robots to enhance operational

excellence across our global manufacturing network,” said Andreas Schick, Chief

Operating Officer, Schaeffler AG. “In collaboration with strong partners like

Accenture, we constantly explore how disruptive technologies from NVIDIA and

Microsoft can increase our flexibility and efficiency. This is how we want to

jointly shape the production of the future.”

“Physical AI is

reinventing industrial automation as it offers efficient ways to train and

control entire fleets of AMRs, mobile adaptive manipulators and general-purpose

humanoid robots,” said Patrick Vollmer, Global Industry Group Lead- Industrials, Accenture. “Our collaboration with Schaeffler, Microsoft and

NVIDIA shows how clients and strategic partners can co-innovate on turning

emerging technologies into solutions to help manufacturers tackle flexibility,

productivity and workforce challenges.”

The companies

developed a proof-of-concept (PoC) demonstrating the benefits AI-powered

simulations can bring to Schaeffler’s factories and distribution centers on

three levels:

1. Planning the

ideal facility: Accenture’s

capability to build digital twins of factories and warehouses on the NVIDIA Omniverse development platform

allows Schaeffler to simulate and identify the best layout for facilities

up-front and thus reduce commissioning times. This includes virtually

positioning production lines and kitting stations for dynamic material flow and

seamless collaboration between humans and robots.

Virtual

commissioning can also help Schaeffler determine the right degree of automation

for each facility. The PoC covers scenarios with different types and

sophistication of physical AI: primarily manual work; AMRs supporting transport

tasks; and adaptive manipulators such as EMMA and general-purpose humanoid

robots in highly automated facilities.

Half of the factory

managers of industrial companies (49%) expect AMRs to be a key element of

future factories and 43% believe humanoid robots will become a standard

component of assembly processes, according to a recent Accenture research report.

2. Paving the way

for physical AI and general-purpose humanoid robots: Accenture and Schaeffler are

starting to adopt Mega, an NVIDIA Omniverse Blueprint, to test robot fleets,

including general-purpose humanoid robots, in industrial digital twins of

factories and warehouses.

The PoC shows

Agility Robotics’ Digit performing material handling, such as tote handling and

transport to kitting and commissioning areas. It also demonstrates how

Sanctuary AI’s multi-dexterous humanoid robot, Phoenix, learns real-world tasks

in Omniverse by observing simulations (Accenture made a strategic investment in

Sanctuary AI in March 2024). An example is compiling spare part kits for

individual orders in one of Schaeffler’s spare part centers. The imitation

learning technique is supported by vision AI applications such as NVIDIA Metropolis, which

captures the movements of human workers and humanoid robots in the real world

and translates them back into simulations in Omniverse.

As Accenture found

in its 2025 Technology Vision,

humanoids are appealing because of their versatility. They will fit quickly and

easily into a human-centric world, accessing physical spaces and participating

in workflows initially designed for people.

“Tomorrow’s

factories require complex collaboration between humans, industrial automation

systems and multi-robot fleets,” said Mike Geyer, head of digital twins at

NVIDIA. “By using Mega and NVIDIA Omniverse to simulate and test various types

of robots at scale in industrial digital twins, Accenture and Schaeffler are

reinventing their industrial operations with physical AI.”

3. Optimising live

robotics operations: Accenture and

Avanade, its joint venture with Microsoft, are collaborating with Schaeffler to

use simulated data from Omniverse to optimise the physical performance of

robots in the warehouse and on the shopfloor – for example, to avoid

congestion. Data from various simulated scenarios is fed into Microsoft Fabric,

a unified, AI-powered data platform. Site managers and workers responsible for

operations can then compare key performance indicators, such as availability,

utilisation and overall equipment effectiveness for these scenarios to identify

potential issues in time to act.

Accenture and

Avanade developed a solution for Schaeffler's production site Schweinfurt,

Germany, that uses MS Fabric in combination with a generative AI-powered factory operations agent.

It helps staff gain production insights and solve issues faster by letting them

ask questions in natural language. Moving forward, virtual factories can be

onboarded, allowing engineers and planners to interact intuitively with

simulation data of robots and production systems, for example, by pulling up

dashboards and changing simulation parameters using voice commands.

Related Stories

Accenture and Siemens launch group to transform engineering and manufacturing

The new business group will bring together 7,000 professionals with expertise in manufacturing and IT to co-develop and market AI-powered solutions.

Read more

Accenture and Schaeffler pave the way for industrial humanoid robots

Movements are captured in the real world and translated back into Omniverse, where humanoid robots can learn them.

Read more

Addverb to enter humanoid robotics with next-gen humanoid in 2025

The new humanoid robot will be an advanced AI agent capable of processing vast volumes of multi-modal data from vision, audio, and touch inputs.

Read moreRelated Products

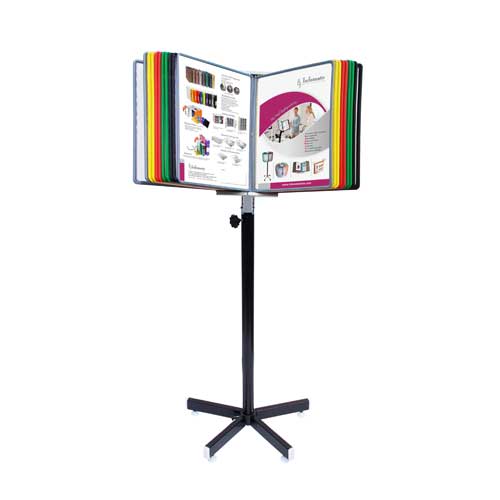

Dna of All Information

Roto Leaner Technology Pvt Ltd manufactures a complete range of display solutions.

Standard Series Stations and Enclosures

Esbee

Industrial Combines/Esbee Electrotech LLP offers standard series stations and

enclosures.

Fire Alarm

Safe Zone is prominent traders and suppliers of the industry, offering a wide range of wireless fire alarm.

Read more