Schedule a Call Back

AI and ML are opening new vistas in robotics: Sameer Gandhi

Articles

Articles- Nov 29,24

- High initial costs: The upfront investment required for purchasing and integrating robotic systems can be prohibitive for many small and medium-sized enterprises (SMEs) in India.

- Lack of skilled workforce: There is a shortage of skilled professionals who can operate, maintain, and program robots, which hampers the adoption of advanced robotic technologies.

- Limited awareness and understanding: Many manufacturers are not fully aware of the benefits and potential ROI of robotic automation, leading to slower adoption rates.

- Infrastructure challenges: Inadequate infrastructure, such as inconsistent power supply and lack of advanced manufacturing facilities, can impede the effective deployment of robots.

- Regulatory and policy barriers: Complex regulatory frameworks and lack of clear policies supporting automation and robotics can create uncertainties for manufacturers looking to invest in these technologies.

Related Stories

The 3D metal revolution

India is rapidly emerging as a frontrunner in the world of 3D metal printing, a technology that is reshaping the way industries approach manufacturing. From aerospace to automotive, healthcare to de..

Read more

Hyundai India partners with Amara Raja for indigenous AGM battery technology

The AMARON AGM batteries, manufactured by ARE&M, have shown remarkable improvements in durability, outperforming conventional CMF batteries by approximately 150%.

Read more

Altem organises 3D printing workshop for innovations in medicine and healthcare

The workshop offered a diverse lineup of sessions focusing on 3D printing applications in surgical education, neurosurgery, orthopaedics, and biomedical engineering.

Read moreRelated Products

Fire Alarm

Safe Zone is prominent traders and suppliers of the industry, offering a wide range of wireless fire alarm.

Read more

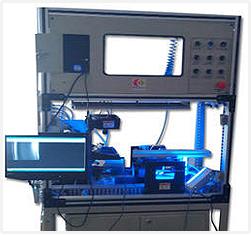

Sorting Automation Systems

Renovus Vision Automation offers sorting automation systems.

Read more

Manual Bagging System

Alligator

Automations provides a wide range of manual bagging systems.