Schedule a Call Back

Die Mould India 2024 sets the stage for innovation and collaboration

Industry News

Industry News- Feb 26,24

Related Stories

Why Precision Tooling is the Backbone of India’s Next Manufacturing Leap

If manufacturing is the body, tooling is the skeleton holding it all together. Dr Dario Maria Fumagalli, President & CEO, Silmax, believes, for India’s rise as a global manufacturing hub, tooling ..

Read more

Godrej Tooling Secures 3 Patents, Strengthening India’s Innovation Drive

Godrej Enterprises Group’s Tooling business earns three new patents in die casting and railway automation, advancing India’s self-reliance, safety, and global manufacturing competitiveness.

Read more

GTW aims to become a global player in customised cutting tools: Tosher Hormusjee

In this interview, Tosher G Hormusjee, Managing Director, GUSTI Tool Works LLP, explains plans to expand capacity, diversify tooling solutions and strengthen exports.

Read moreRelated Products

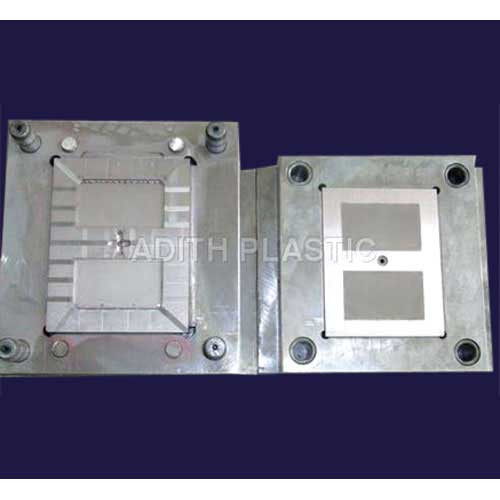

Industrial Moulds

Adith Plastic offers moulds for industrial electronic parts.

Industrial Plastic Moulding Dies

Adith Plastic offers a wide range of industrial plastic moulding dies.

Component Moulds

Innovative Moulds & Dies offers a wide range of plastic component moulds. Read more