Schedule a Call Back

IMTEX 2025 is set to surpass its previous editions: Rajendra S Rajamane

Industry News

Industry News- Dec 19,24

Related Stories

Purvi Products transforms machine tools

The industry is transitioning from traditional tools to automated, high-precision systems.

Read more

The tooling sector should adopt IoT to enhance tool performance: Sunil Joshi

Sandvik Coromant’s 'Manufacturing Wellness' outlook encourages manufacturers to take a holistic perspective that considers all of the interconnected steps of the value chain.

Read more

Dormer Pramet is exploring 3D printing integration to boost products: Amit Raina

The Indian unit plays a crucial role in supporting Dormer Pramet's global business by serving as a strategic manufacturing hub.

Read moreRelated Products

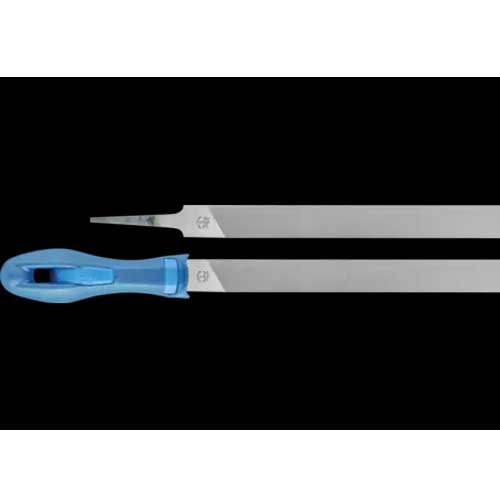

Mill Saw Files Hand

PFERD offers a wide range of mill saw files hand.

Ss Hex Head Bolts

Trychem Metal And Alloys is offering SS hex head bolt.

Cutting Tools

Get Cutting Tools provides a wide range of CNC cutting tools