Schedule a Call Back

Super Forgings building reputation with technology and quality

Industry News

Industry News- Feb 11,22

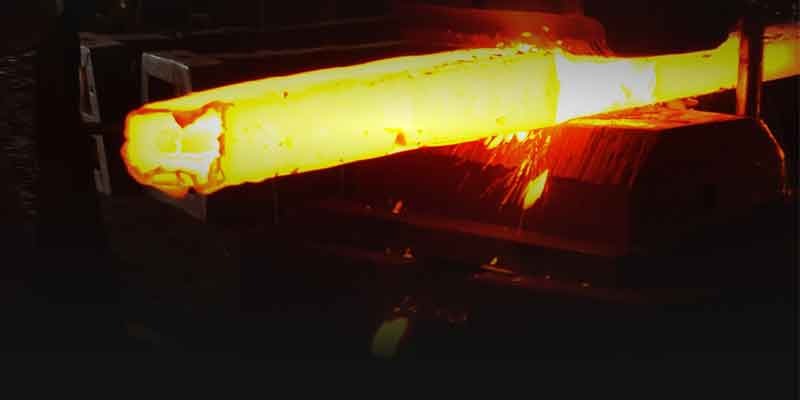

Super Forgings & Steels Ltd (SFSL) is among the leading suppliers and manufacturers of high strength alloyed sophisticated tools and alloyed steels. Located in one of the fastest growing industrial hubs at Howrah in West Bengal and another at Chennai in Tamil Nadu, its journey began in the year 1968 with a variety of alloy and special steels forgings and rolled products. Initially it played an important role in import substitution. Subsequently, it specialised in production of high value and higher grades tool & die steels in special sizes, using the latest technology and carving a niche for its products.

Comprehensive capability

Its in-house designing unit is equipped with all the latest software and skilled personnel who intuitively understand client requirements. Once a meticulous, customised design is in place, the machines take over for a precise metal cut that ensures 100% compliance with even the most complex of customised forging requirements. One of the reasons for the company's success is its modern manufacturing and finishing facilities: 5M. ton capacity Induction Furnace for steel melting; 12" & 14" Hot Rolling Mills and Open Hot Forging Hammers up to 3 ton capacity. In addition, there are various heat treatment units like Bogie-Hearth annealing furnaces, hardening-cum-solution annealing furnace and a tempering furnace. The finishing facilities include Straightening machines for rounds, flats and square sections, Billet Grinding Machines, Reeling Machines, Band Saw Cutting Machines and Power Hacksaw Cutting Machines.

The company has consciously steered clear of using oil fired furnace as a resolution to keep the environment as clean as possible in one of the many steps towards becoming a green company, while supplying high quality products that improve lives and creates a better world.

Consistent Quality is the key

The range of products which includes Forged Rounds, Forged Flats, Forged Square, Rolled Rounds, Rolled Flats and Rolled Squares, conforms to international standards ensuring reliability and consistency.

The emphasis is on in-house process quality assurance thereby minimising the need for subsequent rework. Testing tools like Hardness Testers, Optical Microscopes, Universal Testing Machines, Shadowgraphs and Ultra Sonography Machines are used wherever required.

SFSL operates a quality management ISO/ certified system and is committed to providing high quality products and services to its customers. It comprises a fully equipped laboratory, in-house Spectro, Tensile, Izod, Hardness and ultrasonic guarantee.

A dedicated team of specialists with the necessary hands-on skills look after the complete process control and the employees are always focused on ensuring safety and deliver high quality products that exceed customer’s expectation.

The main objective of its quality control system is to reduce customer’s complaints through Quality Assurance, reduce production of non conforming products, improve productivity and ensure customer satisfaction.

A reputation to uphold

These untiring efforts have paid off and SFSL has earned respect in delivering superlative products that are consistent with international and domestic industry standards of high performance and durability.

At Super Forgings & Steels, the management believes that customers are its lifeline and hence it is conscious of improving existing practices to deliver more value for every penny the company earns. Its laser-sharp focus ensures reliable workmanship, high product quality, timely delivery, transparent communication and an aggressive team that is raring to go.

Related Stories

Moulding the future of manufacturing

Despite the global turmoil, the Indian tooling industry performed exceptionally well in 2023. With emerging segments (like electric vehicles, railways, aerospace, etc) opening up new avenues of grow..

Read more

Forging is a crucial element for success in industries

Forging is considered to be an indispensable process in the manufacturing industry due to its ability to offer precision & versatility, meet the stringent demands of various applications, and enhanc..

Read more

Indian Railways explores export opportunities for Vande Bharat locomotives

The current trains are suitable for broad gauge, customisation may be necessary to adapt to the standard gauges used by many countries globally.

Read moreRelated Products

Robofinish Iron Casting Fettlingrcf

Grind Master Machines Pvt Ltd offers a wide range of robofinish iron casting fettling CF-HD series.

Casting Components

Micro Melt offers a wide range of auto parts casting components. Read more

Robotic Deflashing of Aluminium Casting - RMT Series

Grind Master Machines Pvt Ltd offers a wide

range of robotic deflashing of aluminium casting - RMT Series.