Schedule a Call Back

Servotech has signed MoU with GoUP for EV charger manufacturing unit

Interviews

Interviews- Aug 30,23

Kindly brief us on Servotech Power Systems’ operations and industries served.

Servotech Power Systems is an NSE-listed organisation, founded in 2004 and headquartered in New Delhi. Leveraging our experience of over two decades and expertise in the electronics space, we specialise in developing tech-enabled EV Charging solutions. Servotech offers an extensive range of AC and DC chargers that are compatible with different EVs and serve multiple applications such as commercial and domestic. With our comprehensive engineering capabilities, we plan to play a pivotal role in developing India's EV tech infrastructure. A trusted brand with a strong pan-India presence, our legacy is marked by proven innovation and distribution of high-end solar products, power & back-up products, LED lighting, and UV-C disinfection products, along with medical-grade oxygen concentrators and their makings. Servotech has its hi-tech manufacturing plant in Sonipat, Haryana equipped with advanced machinery and highly skilled manpower.

We are a dedicated manufacturer and always work with a progressive approach to serve domestic and international markets with meticulously-engineered products. So far, we have worked with state government, PSUs, nodal agencies, oil refineries, fuel stations, etc as well as have exported our products in more than 5 countries. We also have deployed thousands of EV chargers at BPCL and Nayara sites in multiple locations of major Indian cities. We have a strong network of over 1000 retailers in India and have also signed a sole distributorship agreement with Dubai-based Al-Ansari Motors to strengthen our footprint in the international market. Servotech comprises high potential and full capabilities to secure a rank among the top three manufacturers of EV chargers. Therefore, aggressively working on bigger expansion plans with viable business strategies.

What are some factors driving the demand for batteries in India?

Continuously increasing demand for electric vehicles across passenger and commercial segments is one of the primary factors that are responsible to drive demand for batteries in India. Homes are also becoming smarter and using different types of electronic devices to complete routine tasks. The usage of electronic devices at home has increased the demand for the required power supply. The existing capacity of grid supply is not enough to meet this demand. Shortage of the required grid supply also proves an important driving factor for increasing demand for batteries.

Besides, government is continuously taking big initiatives to accelerate rapid urbanisation and industrialisation to contribute to the economy which leads to increased demand for electricity. Batteries, especially in the form of backup power solutions, in rural areas with limited or unreliable access to the electricity grid, urban, and industrial settings, are essential to ensure uninterrupted power supply. Batteries prove good off-grid solutions when grid supply is not available.

The telecommunication infrastructure is another domain that essentially requires high-capacity batteries to ensure smooth connectivity in remote areas. The power sector currently produces insufficient energy and it obviously requires huge improvement to successfully overcome the considerable issues of unstable power infrastructure. High capacity energy storage solutions appear to be a feasible amenity to bring positive change in the energy sector but they also need batteries to keep ESS functioning and deliver expected results. Above listed factors are significantly driving the demand for batteries in India.

What are some opportunities and challenges in lithium-ion batteries’ market?

The adoption of EVs is continuously increasing and electric vehicles are penetrating the market with higher sales. They require lithium-ion batteries in huge amounts. Consistently growing sales of EVs also increase the demand for lithium-ion batteries because they are the main components in electric vehicles. These numbers will increase more in the coming years to touch new limits. Lithium-ion batteries also help as an emergency power backup system at home, workplace, and C&I. These batteries additionally play a key role to increase the capacity of the power backup system and provide enlarged backup time. These consistently growing demands provide huge opportunities for all lithium-ion battery manufacturers. Any company with meticulous planning and feasible strategies can reap great benefits from this opportunity to lead in the market. This is undoubtedly a golden opportunity to grow in terms of revenue and growth. The aforementioned information clearly sounds good but there are some highly significant challenges as well which prove big constraints to meet the targets. Unavailability of raw materials, expensive import, and stipulated rules & regulations are a few of them.

Mineral Exploration Corporation Limited (MECL) however has found some lithium reserves in India at J&K and Rajasthan locations but exploration and processing of lithium is still a dream. Expensive techniques, the fragile ecosystem around the reserves, and other important environmental challenges pose big challenges & threats to move further. These challenges might take years to sort out and start lithium mining to ensure easy availability of raw lithium at a reduced price and cut dependency on foreign exports.

There is less availability of raw materials like lithium, cobalt etc. So, how the country is facing that challenge in battery manufacturing?

The battery manufacturing sector is very big, not only in India but across the world, and is currently incapable of meeting the constantly increasing demands in the market. The shortage of key raw materials like lithium, cobalt, etc. is the main reason behind the limited manufacturing of batteries. Importing these raw materials from foreign countries is the only feasible solution to overcome this shortage. China is reportedly the biggest supplier of lithium, cobalt, and other raw materials. Most of the Indian battery manufacturers, including us, import a majority of its requirement from China and it will be difficult to mention the exact percentage of the imported raw materials because the requirement remains market-driven. Expensive manufacturing techniques, ambiguous government policies, and lack of required infrastructure also create multiple hurdles to manufacture lithium batteries in the required quantity and ensure smooth supply to the end-user.

How government initiatives are helping battery manufacturers in India?

Over the last few years, the government has introduced consistent policies, and regulatory support along with the required framework for the development of the amicable EV ecosystem in the country. FAME II scheme delivered good results in the last few years and now ACC (Advanced Chemistry Cell) PLI scheme is expected to help the nation save millions against the import of crude oil and enhance the share of renewable energy at the national grid level. This government initiative also emphasises on optimizing domestic value addition and making India globally competitive as far as battery manufacturing capabilities are concerned.

As per the guidelines of ACC PLI program, manufacturers essentially have to set up the manufacturing facility within a period of a maximum of two years after getting the approval and the applicable incentives will be disbursed later that too after continuously selling batteries that are manufactured indigenously. The disbursal time may span up to a period of over five years or even more. These guidelines clearly demonstrate the government’s determination toward creating a world-class EV ecosystem in the country as soon as possible. The provision of disbursing incentives on the basis of continuous selling of batteries will also give confidence to manufacturers to successfully run their battery manufacturing units for a long time and receive government support to escape all roadblocks.

What are your growth plans for the coming future?

We are already a renowned brand in the EV charger manufacturing industry and have secured a respected place in the list of most competent manufacturers. In order to enhance our manufacturing capabilities, we have established our subsidiary Techbec Green Energy Private Limited. Servotech also has signed a MoU with GoUP, in line with Uttar Pradesh Electric Vehicle Manufacturing and Mobility Policy 2022, to set up an EV charger manufacturing unit. This upcoming plant is a 300 crore. investment and will be partially operational in the first quarter of 2025 and will have the annual capacity of manufacturing around 10,000 EV chargers. This plant will additionally create over 500 jobs. Servotech expects to touch the revenue targets of 2,000-3,000 crore in coming years while supporting and strengthening indigenous manufacturing and securing a place among the top 3 EV charger manufacturers. Servotech will construct its new plant in Uttar Pradesh in a campus-inspired style as well as will maintain a state-of-the-art infrastructure along with a world-class R&D facility equipped with the latest machinery and amenities. Servotech maintains a progressive approach and consistently works with big expansion plans for future growth. Since beginning in 2004, Servotech has registered exponential growth in the last two decades. During this long & successful journey, we have offered an extensive range of products including solar panels, solar inverters, solar batteries, AC & DC EV chargers, and more.

Related Stories

Will solar manufacturing glow in India as renewable energy demand surges?

While India has successfully increased domestic solar module production, import of solar cells remains high. As India plans to add 60-65 GW of solar capacity, will it be a sunshine moment for solar ..

Read more

India is more than ready to invest in next-gen manufacturing: Raman Bhatia

In this interview with Rakesh Rao, Raman Bhatia, Founder & MD, Servotech Renewable Power System Ltd, explores the evolutionary journey of Indian renewable energy sector.

Read more

Servotech strengthens solar manufacturing with 27% stake in Rhine Solar

By capitalising on Rhine Solar’s advanced infrastructure, its ALMM-accredited facility, and extensive experience in solar panel production, Servotech is well-positioned to establish large-scale so..

Read moreRelated Products

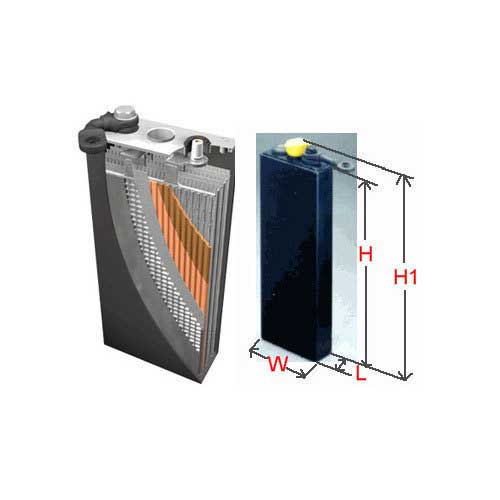

Forklift Battery

Aatous International is a manufacturer and solution provider of a wide range of forklift battery.

Kusam Meco -Wrist Type High Voltage Alarm

‘KUSAM-MECO’ has introduced a new wrist Type High Voltage Alarm Detector - Model KM-HVW-289 having a wide sensing range from 1kV-220 kV AC.

Servotech Power Systems files 2 patents for energy management technologies

Servotech Power Systems, a leading manufacturer of EV chargers and solar solutions, has announced that it has filed two patents for innovative energy management technologies in order to facilitate gri Read more