Schedule a Call Back

United Grinding Group hosts second umati Hackathon

Articles

Articles- Jun 26,23

A umati hackathon is when around thirty digitalisation experts from the machine and plant engineering sectors of different industries meet and network machines together, implement standardised data models, and generate and test code for two days. After 2022, it is the second such event, this year, it took place in May in Steffisburg, Switzerland, at Fritz Studer AG, the cylindrical grinding machine specialist of the United Grinding Group. “As the host of this event, we enable a creative platform that brings developers from different companies together – not for their own purpose, but always with a focus on specific customer benefits,” said Christian Josi, Head of Digital Engineering at the United Grinding Group. We are big proponents of umati and have supported the initiative since day one.

Umati stands for “Universal Machine Technology Interface” and aims to introduce a universal manufacturer-independent data interface for machines based on OPC UA. Thanks to this interface, machines on the shop floor can communicate with each other and with their production environment in a uniform language. The VDW and VDMA are the initiators and sponsors of this initiative. “Standardisation of communication and interfaces is enormously important for machine tools and the industry of the future,” said Dr Alexander Broos, Head of Research and Technology at VDW and project manager of umati. "Without this standardisation, there will be no digital transformation in production. A uniform language is an essential requirement for machines from different manufacturers to be able to exchange data.

This uniform language can only be developed in cooperation with the various machine manufacturers. Around 310 partners from all over the world are now involved in umati. All of them share the goal of making their customers’ work lives easier and increasing productivity in production by harnessing the potential of digitalization. This is achieved with umati through the implementation of the OPC UA communication and interface standard, which can now be used for a wide range of machine tool applications through numerous sub-specifications, so-called companion specifications.

The advantages are:

The focus of the most recent hackathon was on the integration of existing machine tools using the OPC 40501 ‘UA for Machine Tools’. While new machines are predominantly equipped with the integrated umati standard today, there is great potential in existing machines, known as ‘brownfields.’ The importance of ‘Brownfield’ is so significant, because machines in general, and machine tools in particular have a long service life, and several machines of different years of manufacture, can often be found in one production. At the hackathon, the experts impressively demonstrated that umati is also suitable for existing machines - regardless of the year of manufacture and the brand.

Another showcase from the Hackathon in Steffisburg was the implementation of the first standardized energy consumption data of the ‘Energy Monitoring’ expansion of the OPC 40001 ‘UA for Machinery,’ which is currently under development. Electrically and pneumatically operated consumers provided their values in a uniform language on the data interface. This further development is an example of how umati does not stand still, but makes advancements and adapts to constantly changing customer needs.

The event was also a complete success from the perspective of Christoph Plüss, CTO of the United Grinding Group. "I’m always thrilled to see the dynamics and team spirit that emerge when the experts from the different companies work together. Umati has succeeded in combining the expertise of manufacturers in an initiative that may even be competitors in day-to-day business to pursue a common goal: to drive forward digitalisation and thus offer the customer added value. Only by joining forces can an industry standard be created and developed, and I am convinced that this is the right path and that our customers will also benefit from it." The commitment to the umati initiative thus also contributes to the ultimate goal of the United Grinding Group to make their customers even more successful.

Related Stories

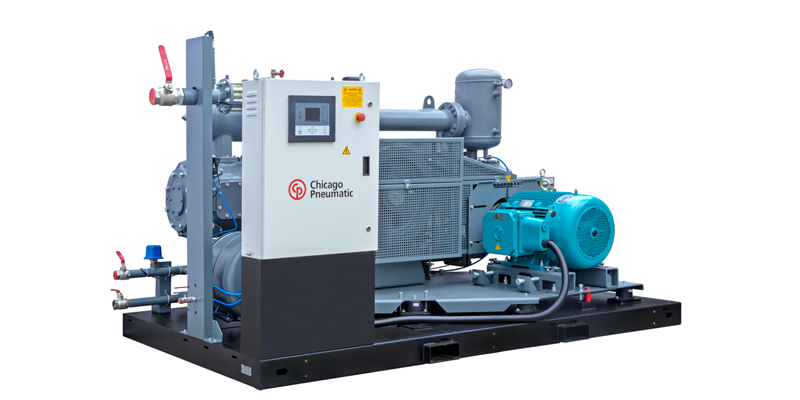

Top eight maintenance tips to extend the lifespan of reciprocating compressors

In this article, Siddhartha Guin, Business Line Manager (CTS), Chicago Pneumatic Compressors, India, shares essential maintenance practices to help extend the lifespan of these vital machines. From ..

Read more

Japan’s KITZ Corp buys Horizon Polymer Engineering

The Gandhinagar based Horizon Polymer Engineering manufactures and sells fluoropolymer-lined products, such as pipes, fittings, valves, tanks and vessels, mainly for the fine chemicals market.

Read more

Tata Technologies buys Germany’s ES-Tec Group to boost global automotive ER&D

Tata Technologies’ acquisition of ES-Tec Group for €75 mn will strengthen its engineering research & development (ER&D) in ADAS, connected driving and digital engineering while deepening ties wi..

Read moreRelated Products

Precision Cutting Tools1

S S Trading Corporation offers a wide range of precision

cutting tools.

Slotting Head Unit for All Cnc Turn Mill Centers

Sphoorti Machine Tools Pvt Ltd offers a wide range of

slotting head unit for all CNC turn mill centers.

Slotted Tool Disc and Tool Holders

Prominent Machine Tools offers a wide range of slotted tool disc and tool holders.