Schedule a Call Back

Six ways to save energy in welding industry

Articles

Articles- Jul 28,23

2. Choose smart solutions to save energy

Welding refers to the uniting or fusing of pieces by using heat and/or compression so that the pieces form a continuum. That is why the welding industry is, by nature, energy intensive. A specific volume of molten metal needs a certain amount of energy. Simply put, less molten metal means less energy consumption. Smaller groove volume yields significant cost savings through reductions in welding time, filler material, and energy consumption. Reducing the groove angle can significantly increase the efficiency and productivity of welding heavy metal structures. Kemppi Reduced Gap Technology (RGT) is an intelligent welding solution that enables reliable narrow gap welding of materials with a thicknesses of up to 30 mm, without the need for special equipment or accessories. Together with other special processes, RGT increases welding efficiency and reduces overall energy consumption. Investing in smart solutions saves time, energy, and a welder’s nerves.

3. Always choose the optimized set-up for your welding work

Did you know that the ultimate way to save energy during welding is to use thick welding cables with the optimal length? This may sound too simple, but it is true. The extra length of welding cable and the minimum size alone, i.e. the cross-sectional area of the welding cables will ultimately lead to energy loss. And, of course, good quality copper cables are more reliable and economical in the long run than their cheaper mass-produced cousins. Choosing the correct cables will pay for itself through energy savings (refer Table 1).

4. Use the latest technology to save energy

No matter how you approach it, welding is energy-consuming yet necessary work in today’s industry. However, the latest technologies already pay great attention to energy efficiency and environmental issues. As a responsible manufacturer, we at Kemppi invest a lot of resources in the R&D work to further develop our welding machines to reach the next level – in terms of quality, performance, and energy efficiency. This work consists of careful material choices, shaping industry standards, and improving the existing technologies (while also adapting new ones). Energy efficiency is one part of our work. With Kemppi, your welding is energy-conscious welding.

5. Invest in the future

Global energy demand is constantly growing. We need to increase the use of renewables to reduce carbon emissions. Kemppi participated in Power2Power, a European co-funded innovation project to enable sustainably competitive European technologies and a strong innovation and production capacity. By working together, we can stand strong in front of today’s challenges and find ways to reduce energy consumption. Collaboration, a strong R&D commitment, and new innovations are Kemppi’s way toward a more sustainable tomorrow. Kemppi aims to pioneer welding technology while also establishing our voice as an opinion leader moving towards a greener industry. By being aware of what is happening around us, we can all care for our share and take action on ways to build a better tomorrow.

Power2Power has received funding from the ECSEL Joint Undertaking (JU) and National Funding authorities from eight involved countries, including Austria, Finland, Germany including the Free States of Saxony and Thuringia, Hungary, the Netherlands, Slovakia, Spain and Switzerland.

6. Do not settle for anything below the standards

In 2021, the European Union set an Ecodesign Directive to make sure that welding machines (among other energy-related equipment) sold in the European market comply with the norms and standards required and that they are cost-efficient to operate. By investing in a welding machine made in Europe, you can be sure that the manufacturer is responsible, that spare parts will be available even after production has ended, and that your welding machine complies with eco-friendly consumption standards. As one of our own initiatives and following the practice of continuous development, Kemppi has already complied with these standards many years before the Ecodesign Directive took effect.

Kemppi_energy 3

Many small streams make one big river. It is not possible to change the world overnight, but it is possible move forward by taking action in small ways. Reducing energy consumption and finding more energy-conscious ways of working are required from all of us – energy-wise thinking is critical to making the changes that will secure our common future.

About the author:

Anu Rousku was the Marketing Communications Specialist at Kemppi Oy until September 2020. She is currently working as a Content Specialist in an advertising agency. She is an experienced professional in content marketing with a demonstrated history of working in the industrial B2B sector.

(This article was originally published on "Welding Value by Kemppi" website)

Related Stories

Cost Savings Through Optimising Pump Performance

Optimisation of pump operations, a piece of equipment that is widely installed across industries, offers significant opportunity for cost savings. In this article, Sulzer reveals how optimising pump..

Read more

ABB drives energy efficiency in Indian industries with high-quality motors

ABB India's IEC low voltage motors are not just enhancing industrial processes, but are also leading the charge towards energy efficiency in Indian industries, writes Karthik Muthuveeran.

Read more

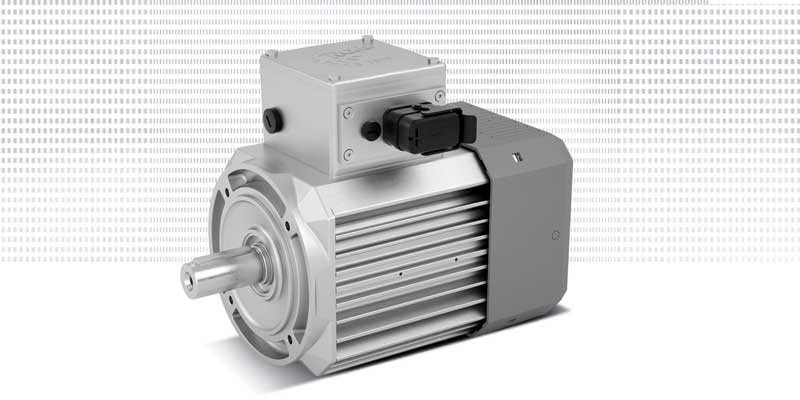

NORD’s IE5+ synchronous motors saves CO2 and material

The new high-efficiency IE5+ synchronous motors series from NORD requires significantly less rare earth elements than its predecessor

Read moreRelated Products

Hardy - Chassis Mounted Weighing Card for Rockwell PLCs

Kore Mechatronics Private Limited offers a wide range of

hardy - chassis mounted weighing card for Rockwell PLCs.

Tack Welding Machine

Invent Weld

Automation offers a wide series of tack welding machines.

Bench Welding Positioner

Toss Weldtronics

offers a wide range of bench welding positioners.