Schedule a Call Back

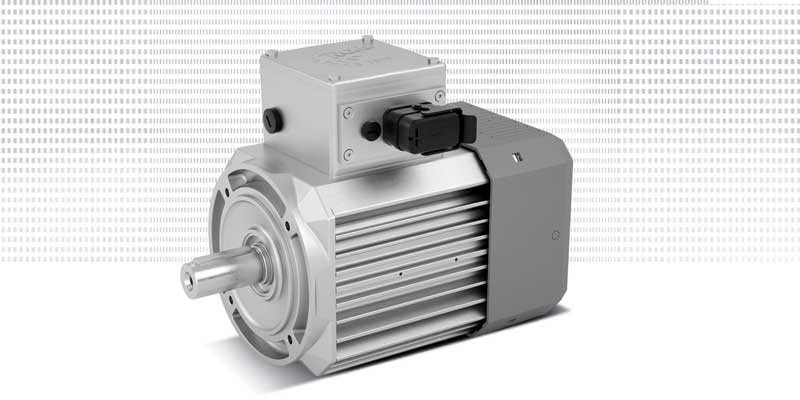

NORD’s IE5+ synchronous motors saves CO2 and material

Articles

Articles- Nov 28,23

- IE3 asynchronous motor with 0.75 kW, 83% motor efficiency and helical bevel gear unit

- IE5+ synchronous motor with 0.75 kW, 93% motor efficiency and helical bevel gear unit

- Period: 16 operating hours per day, which corresponds to 4,000 operating hours per year

- Energy savings of the IE5+: around 400 kWh per year

- Reduction of emissions: 0.15 t CO2 per year (with a CO2 emissions factor of 366 g/kWh)

Related Stories

Honeywell Launches Hybrid Heating to Cut Industrial Energy Costs and Emissions

Honeywell’s Hybrid Heating Solution enables manufacturers to switch between gas and electric heat in real time, helping optimise energy costs, cut emissions and support the energy transition.

Read more

Air-Saving Vacuum Ejectors Cut Energy Use by Up to 90% in Automotive Plants

Air-saving vacuum ejectors are helping Indian automotive manufacturers reduce energy costs, cut carbon emissions and achieve rapid ROI while ensuring reliable, zero-defect production, shares Rajesh ..

Read more

How India Can Build Manufacturing Strength in a VUCA World

As global manufacturing resets under VUCA pressures, India stands at a strategic inflection point, balancing resilience, technology, sustainability and leadership to shape future supply chains, says..

Read moreRelated Products

Ph Fwd/ Rev Motor Protection Ssrs

Insys Electrical & Controls offers a wide range of PH FWD/ REV motor protection SSRs.

Commutator Motors

J D Automation provides a range of commutator motors, which are also

known as permanent magnet DC motors.

Compact Speed Vector Drives

Confident Automation offers compact speed vector drives.