Schedule a Call Back

Nextgen Plasma to offer robotic welding solutions at IMTEX Forming 2024

Articles

Articles- Dec 29,23

The Kolkata-based Nextgen Plasma will showcase the latest automated & robotic welding solutions at IMTEX Forming 2024 (Hall 3A, Stall B 118). These solutions optimise production workflows, enhance overall manufacturing capabilities and with excellent price to performance ratio. At the heart of Nextgen Plasma's line of automated welding systems lies their sophisticated laser-seam tracking technology, incorporating latest IGBT Inverter based Synergic GMAW Pulsed and GTAW Pulsed welding processes. This allows for unparalleled control and accuracy in the welding process, resulting in high-quality, defect-free welds. Designed and manufactured by Nextgen Plasma at its plant near Kolkata, these systems showcase the country's growing prowess in cutting-edge manufacturing process, technology and innovation.

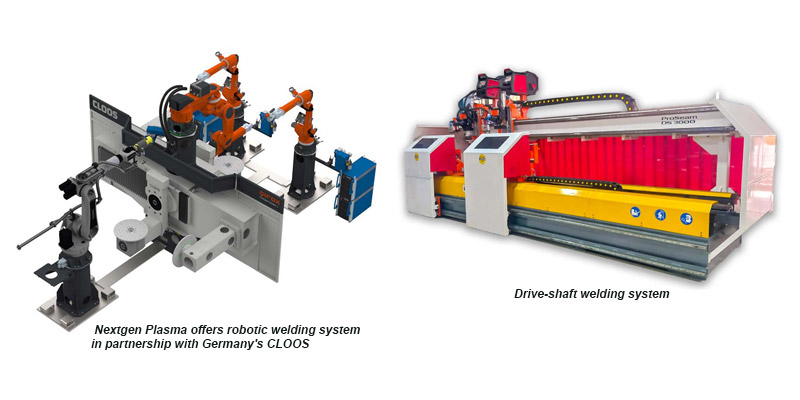

Parallel to its automated welding systems, Nextgen Plasma also offers customised robotic welding systems from CLOOS, Germany. These robotic systems are tailored to accommodate various welding applications, ranging from heavy-duty welding applications to intricate precision welding tasks. This collaboration combines Nextgen Plasma's expertise in advanced plasma welding with CLOOS' proficiency in robotic welding systems. The result is a synergistic approach that promises to revolutionise the welding industry by delivering highly efficient and precise solutions. With the integration of CLOOS' state-of-the-art robotic welding technology, Nextgen Plasma's systems are poised to offer unparalleled automation, accuracy, and productivity in welding processes. This partnership not only showcases the commitment of both companies to pushing the boundaries of innovation but also signals a significant leap forward in the capabilities of robotic welding systems for various industrial applications.

Nextgen Plasma will also display at IMTEX Forming 2024 the latest welding solutions such as:

- Linear welding system for rolled components: The PROSEAM line of long seam welding system represents a cutting-edge solution in streamlining the welding process for longitudinal joints with unmatched precision. This advanced system utilises PLC based controls and servo driven torch on LM guides to ensure consistent and high-quality welds along the length of a workpiece, significantly reducing the margin of error associated with manual welding.

- Circular welding system for formed components: The PROSEAM line of circular seam welding system is used for circumferential joints with unmatched precision. By employing real-time arc monitoring, the system adapts to variations in material thickness and joint configurations, providing a versatile solution for diverse welding applications.

- Customised welding automation for specialised applications: These customised systems play a pivotal role in addressing the unique demands of specialised welding applications in the industries, ranging from earth-movers, aerospace to automotive and beyond. The advent of advanced technologies such as artificial intelligence, and machine learning has enabled the development of highly efficient and precise welding solutions.

At IMTEX Forming 2024, Nextgen Plasma will also showcase customised job holding fixtures, toolings and other accessories tailored for robotic welding systems, delivering precision and efficiency to modern engineering. These fixtures are meticulously crafted to securely hold workpieces in optimal positions, ensuring consistent and accurate welding results. Prioritising customisation meets the unique needs of Nextgen Plasma's clients, offering a comprehensive range of solutions that enhance productivity and reduce downtime.

For details, contact Nextgen Plasma, Kolkata, on Tel: +91 33 2229 9771; Mob: +91 83350 42505; and Email: sales@nextgenplasma.com

Related Stories

Achieve Maximum Freedom in Mobile MMA Welding with the Ignis Battery

The Ignis Battery impresses with functions that make welding easier, safer, and more efficient. HotStart and SoftStart ensure optimum ignition for rutile, basic, or CEL electrodes.

Read more

Fronius Unveils Groundbreaking Welding Innovations at SCHWEISSEN & SCHNEIDEN

Fronius once again focused on the key drivers in the industry, demonstrating how modern welding technology can be economical, resource-efficient, and user-friendly.

Read more

Raising Output for TruBend Bending Machines

Trumpf drives efficiency with new Fronius LaserHybrid welding system, which significantly improves the weld quality of the machine frames, increases the welding speed, and saves valuable working tim..

Read moreRelated Products

Hardy - Chassis Mounted Weighing Card for Rockwell PLCs

Kore Mechatronics Private Limited offers a wide range of

hardy - chassis mounted weighing card for Rockwell PLCs.

Tack Welding Machine

Invent Weld

Automation offers a wide series of tack welding machines.

Bench Welding Positioner

Toss Weldtronics

offers a wide range of bench welding positioners.