Schedule a Call Back

IOT solution for machine safety

Articles

Articles- Sep 30,22

Having a manufacturing facility in place that allows machines to monitor their own safety in the workplace shows industry 4.0’s potential. This can be made possible by introducing the Internet of Things (IoT), an intelligent technology that leverages AI (Artificial Intelligence) and machine learning capabilities. It can facilitate machines to detect how frequently machine guards have been moved or if they need to be replaced. The advancement of technology creates an environment for a smart workplace.

More about IoT in machine safety

IoT in a space where machines are actively used in the workplace builds the most effective ways to enhance safety. The technology assists companies by improving the majority of their working conditions, including data collection, operation execution, and productivity enhancement.

However, it must be noted that IoT solutions won’t protect the machines entirely in risky industries. But they can alert managers early on, allowing them to address a number of threats and prevent them from happening.

With IoT technologies, companies can monitor machines’ operating conditions and external defects and effectively limit machines’ exposure and risks to accidents.

Let’s see how IoT brings in solutions for machine and worker safety to provide a secure working environment.

Monitoring safe work with IoT sensors

IoT sensors and solutions enable the collected data to be analyzed efficiently. The sensors monitor workers’ conditions in real-time when they perform hazardous activities or work at such locations.

The three fundamental components of IoT sensors are:

IoT-based smart devices are able to figure out the trail of breadcrumbs that points out to some bigger issues influencing the company’s production. For instance, suppose a company’s production manager detects high usage of an interlocked guard door which is interfering with the seamless production process. Further on discussing the issue with the operators, the manager might find out that they are frequently opening the interlocked door to fix a malfunctioning device and they need to either repair or replace it as soon as possible to fix the problem.

Use of advanced data analytics

With advanced data analytics, companies can come up with better business decisions. They can equip IoT devices to process complex data and implement solutions. The augmented devices with smart capabilities enable safety systems to reach the next level. For instance, companies might use computer vision frameworks to inspect companies for safety risks. It can fnd anomalies even from the vibrations of machines in use.

Schmersal is working on an effective IoT solution for the industry, which will include some of its new products for machine safety:

Identifying the risks beforehand

IoT devices collecting safety data for a long period enables companies to track the machine performance over time. With these insights, managers can predict when a particular device will not be able to run in the near future. As the IoT services use data on machines’ usage or age, the prediction tends to come up as accurate in the majority of cases.

Thus, maintenance staff would be able to replace the devices prior to their failure. Also, it ensures that device replacement takes place under the planned maintenance downtime.

The smart machine would detect any wear in the device, recommend a replacement period, and place an order for delivery of a new part.

The bottom line

IoT for machinery safety automatically ensures long-term safety for the entire workplace as well. The smart sensors and devices in the workplace analyse data and use it to build safety strategies and occupational health for employees. Companies not investing in IoT solutions are missing out on the opportunity to save operational significant costs and time. Whether it’s about taking care of machinery or human workers at an organisation, IoT can be beneficial in transforming the work environment.

Courtesy: Schmersal

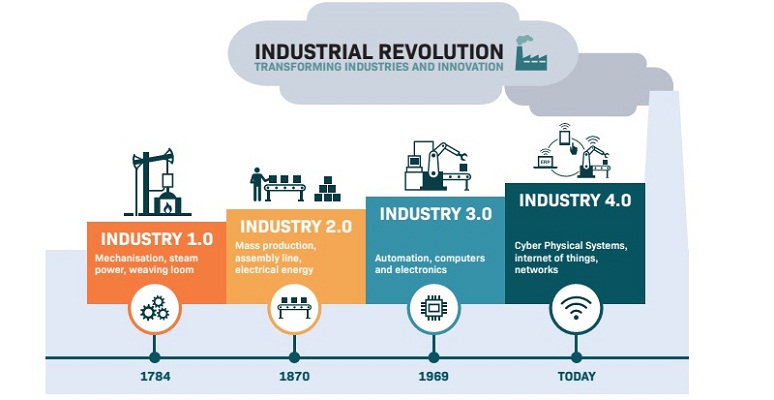

Industry 4.0 is the name of the fourth major revolution in the history of industry. This involves the digitalisation of industrial production and thus the connecting of people, machines and products with the help of information and communication technology. In the following, the essential aspects of Industrie 4.0 are roughly described:

In order for the objects involved in the production process to be able to communicate with each other, they are equipped with storage media, communication solutions and sensors, as well as being connected to the Internet (Internet of things – IoT). Through this digital monitoring of all objects, large amounts of data (Big data) are collected and analysed. The use of artificial intelligence (AI) makes it possible to recognise patterns and react independently.

Source: https://www.gambit.de/wiki/industrie-4-0/

Related Stories

India is at a pivotal ‘Make in India’ inflection point: Manoj Patil

In this interview, Manoj Patil, Promoter and Managing Director, Patil Automation Limited, outlines its growth journey, capacity expansion, acquisitions, design-led approach, market challenges, and t..

Read more

Manufacturing Excellence in the Age of Integrated Automation and Industry 4.0

Manufacturing leadership is shifting from scale-driven efficiency to integrated, data-led systems that deliver resilience, sustainability and enterprise-wide performance through Industry 4.0 and aut..

Read more

Resilience in Metal: Forging the Make in India Future in a VUCA World

The article examines how India’s stainless steel sector can turn global volatility, CBAM and supply risks into strategic advantages through sustainability, quality enforcement and digital transfor..

Read moreRelated Products

Digimatic Smart Caliper

Veekay Industries offers a wide range of digimatic smart caliper.

Compact Fmc - Motorum 3048tg With Fs2512

Meiban Engineering Technologies Pvt Ltd offers a wide range of Compact FMC - Motorum 3048TG with FS2512.

Digital Colony Counter

Rising Sun Enterprises supplies digital colony counter.