Schedule a Call Back

Innovative heating solutions

Articles

Articles- Jun 07,24

The tremendous progress of electronics and electrical manufacturing has required advances in multiple production elements, with heating technology being one of the most crucial ones. In this highly competitive industry, advanced heating solutions are now at the forefront of increasing productivity, raising quality, and cutting costs.

Heating technology is essential to the electronics and electrical manufacturing industries for operations including soldering, reflow, heating, and cure. Inefficient aspects of traditional technologies include slow processing durations, energy waste, and uneven heat distribution. However, a number of significant advancements in improved heating technology are tackling these issues:

Induction heating: This technique heats conductive materials directly by means of electromagnetic fields. It is extremely effective, ensuring exact control over the operation and minimising energy loss through quick, localised heating. Soldering applications benefit greatly from induction heating because it produces high-quality junctions with little to no temperature influence on neighbouring components.

Infrared (IR) heating: To transmit heat, IR heating uses infrared radiation, as it heats objects directly without warming the surrounding air, it is incredibly efficient. It provides accurate temperature control and rapid heating rates, infrared heating (IR) is widely utilised in reflow soldering and curing operations in the electronics manufacturing industry.

Laser heating: This method offers remarkable control and precision by using laser beams to produce concentrated heat. It is perfect for tasks like surface treatment and micro-soldering that calls for exact precision. Automated production lines can benefit from the integration of laser heating systems, which increase productivity and uniformity.

Microwave heating: This method heats objects from the inside out by using microwave radiation. It works very well for procedures where even heating is necessary, such as grinding and drying. Moreover, energy-efficient microwave heating lowers the total power used in manufacturing processes.

Efficiency and quality enhancements

Modern heating techniques have a major positive impact on the productivity and quality of electronics and electrical manufacturing. Here are a few of the main advantages:

Energy efficiency: These technologies lower overall energy usage by accurately directing heat where it is needed and avoiding energy loss. This decreases the carbon footprint of production operations, which helps sustainability programs as well as cutting operating expenses.

Speed and throughout: Production times are accelerated by fine and quick heating capabilities. Faster processing is made possible by technologies like induction and laser heating, which boost throughput and satisfy the expanding demand for electronic gadgets.

Improved product quality: Accurate temperature management guarantees repeatable outcomes, which lowers errors and rework. Modern heating techniques reduce thermal stress on parts, increasing product longevity and reliability.

Flexibility and scalability: Contemporary heating systems are made to be flexible and scalable to a range of manufacturing settings. Due to their simple integration into current production lines, manufacturers are able to expand their operations without having to make major overhauls.

Challenges and future directions

Despite the noteworthy progressions, obstacles nonetheless exist in the extensive integration of these technologies. For many producers, the necessity for specialised knowledge and high upfront expenses can be obstacles. To further enhance these technologies, increase their affordability, and broaden their applicability to new materials and processes, more research is also necessary.

In the future, the manufacturing of electronics and electrical components could undergo a revolution thanks to the combination of sophisticated heating technologies and Industry 4.0 concepts. Real-time heating process optimisation is possible with smart heating systems that have sensors and AI-driven controls. This increases efficiency and lowers waste. These technologies will surely become more and more important as they develop to satisfy the demands of a world that is becoming more and more electronic.

Author Info

Dhawal Gupta, Co-Founder, Subhot Enterprises

Dhawal Guptais the co-founder of Subhot Enterprises. The expansion and prosperity of Subhot Enterprises have been greatly attributed to his vision and leadership. The company has grown immensely, turning over ?600 million during his leadership.

Related Stories

IMTEX Forming 2026: Charting the Next Chapter of India’s Metal Forming Ecosystem

IMTEX Forming 2026, Asia’s largest metal forming and manufacturing technology exhibition, is set to return to Bengaluru from 21–25 January 2026.

Read more

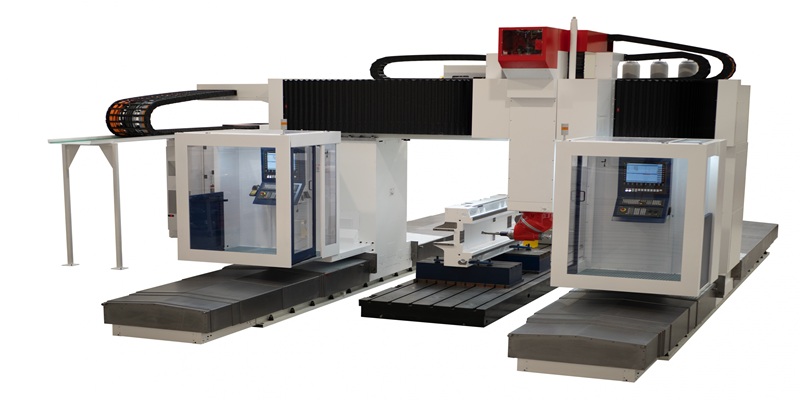

Powermill G3 HPC3 Showcases Italian Excellence in Large-scale Precision Milling

Combining robustness, precision and Industry 4.0 connectivity, the Powermill G3 HPC3 exemplifies Italian manufacturing excellence for large-scale, high-accuracy machining.

Read more

Hannover Messe 2026 to focus on automation & digitalization, adds Defense Area

At the upcoming Hannover Messe, AI will be a recurring theme throughout all the halls, and will play a central role on almost all stands.

Read moreRelated Products

Integrated Electric Gripper S Series

IBK Engineers Pvt Ltd offers a wide range of integrated electric gripper S series.

Geared Electric Motors

Delco Fans Pvt Ltd offers single phase capacitor run and three

phase geared Instrument motors, totally enclosed face/foot mounted.

“Kusam-Keco” Partial Discharge Acoustic Imager - Model - Km-pdai

‘Kusam-Meco’ has introduced a new “Partial Discharge Acoustic Imager Model KM-PDAI.