Schedule a Call Back

Industrial hydraulic equipment powers efficiency and sustainability

Articles

Articles- Nov 29,24

- Energy efficiency and eco-friendly solutions: One of the most significant trends in the market is the development of energy-efficient hydraulic systems. Traditional hydraulic systems often rely on large, inefficient pumps and motors, which can waste energy, increase operational costs, and contribute to environmental pollution. However, newer systems focus on optimizing energy usage by incorporating advanced technologies such as variable-speed drives, improved seals, and low-friction components. These innovations help reduce energy consumption, making the systems more sustainable while simultaneously improving their performance.

- Smart and IoT-integrated hydraulic systems: Another important development in the industrial hydraulic equipment market is the integration of smart technologies. With the rise of the Internet of Things (IoT), hydraulic systems are becoming more connected, offering real-time monitoring and diagnostics. Smart sensors embedded within hydraulic systems can track performance, detect potential issues, and provide valuable insights into system health. IoT-enabled hydraulic equipment can alert operators about necessary maintenance before a failure occurs, thus preventing costly downtime and improving productivity. These advancements in predictive maintenance are helping companies save on repair costs while extending the lifespan of their equipment.

- Compact and lightweight designs: With industries seeking to improve space utilisation and portability, hydraulic equipment is becoming more compact and lightweight. Modern hydraulic systems are designed with smaller, more efficient components, allowing for easier integration into machines that require a small footprint. These innovations are particularly important in sectors like construction and agriculture, where machinery must be both powerful and mobile. The trend toward lightweight design is also contributing to fuel efficiency in mobile equipment. Smaller and more efficient hydraulic systems reduce the weight of machines, resulting in lower fuel consumption, reduced emissions, and increased operational efficiency

- Adoption of electric and hybrid systems: Electric and hybrid hydraulic systems are gaining traction as industries aim to reduce their reliance on traditional internal combustion engines. Hybrid systems combine the power of hydraulics with electric drives to optimize energy use, offering improved efficiency and reduced emissions. Electric actuators, in particular, are being integrated into hydraulic systems to replace traditional hydraulic pumps, reducing noise levels, energy consumption, and maintenance costs.

Related Stories

Harting Launches PushPull V4 Power QuickLock Connectors

Harting unveils PushPull V4 Power QuickLock connectors with Han QuickLock technology for fast, tool-less field assembly in compact industrial and outdoor applications.

Read more

Honeywell–TCS Partner to Drive Enterprise-Wide Autonomy

Honeywell and TCS join forces to integrate OT and IT, enabling AI-driven autonomy, real-time intelligence and improved efficiency for building and industrial operators.

Read more

Honeywell Launches Hybrid Heating to Cut Industrial Energy Costs and Emissions

Honeywell’s Hybrid Heating Solution enables manufacturers to switch between gas and electric heat in real time, helping optimise energy costs, cut emissions and support the energy transition.

Read moreRelated Products

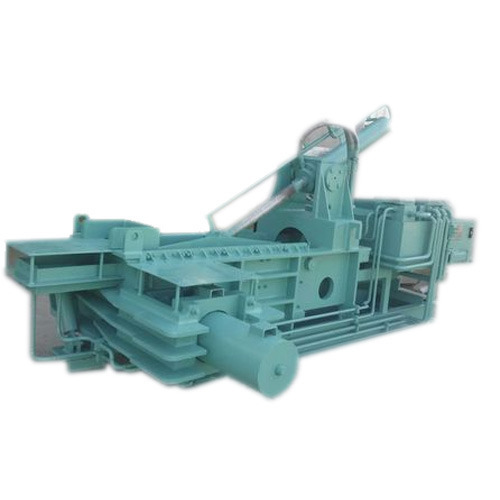

Baling Machine

Mask Hydraulic Machineries provide triple action scrap baling machines. Read more

Manifold Block

Om Shakthi Hydraulics offers a wide range of hydraulic manifold blocks. Read more

Exclusive Hydraulic Fittings

Supreme Engineers is engaged in manufacturing and supplying an exclusive range of hydraulic fittings. Read more