Schedule a Call Back

"Dormer Pramet has ambitious growth plans in Asia, with a focus on India"

Interviews

Interviews- Apr 30,24

Related Stories

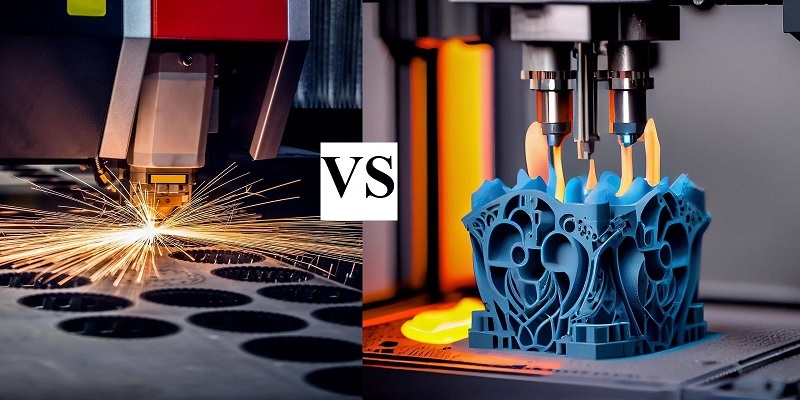

Intersection of 3D printing and laser cutting: A new paradigm in manufacturing

The intersection of 3D printing and laser cutting remains a niche area. However, it should gain prominence when people learn about use cases that demonstrate versatility and viability, says Emily Ne..

Read more

Pune Machine Tool Expo 2024: Connecting the dots in manufacturing

Exhibitors will showcase everything from metal cutting and metal forming to welding, automation robotics, Industry 4.0, and 3D Printing, and visitors can expect to see some groundbreaking innovation..

Read more

FACTEQ 2024 to aid safe, sustainable, and eco-friendly solutions in factories

FACTEQ along with Pune Machine Tool Expo – organised by Indian Machine Tool Manufacturers' Association (IMTMA) - will bode well for the development of factories in and around Pune, the western and..

Read moreRelated Products

Hydraulic Bandsaw Machine, Swing Type

Multicut Machine Tools offers swing type hydraulic bandsaw machines.

Automatic Back Spot Facing Tool

Shenoy Engg Pvt Ltd offers automatic back spot facing tool.

Plas in-line Rotary Pipe Cutters

Arizona Tools Company offers a wide range of in-line rotary pipe cutters for plastic pipe.