Schedule a Call Back

Critical Manufacturing displays advanced MES system at Hannover Messe

Articles

Articles- Mar 21,23

The landscape for manufacturing execution system (MES) has changed dramatically over the past few years. Historically, MES has been cumbersome, leaving manufacturers unable to embrace new advancements because of the difficulty of evolving and upgrading the system. Today, however, these platforms offer tremendous flexibility, scalability and ease of use. To enable easy deployment across multiple sites and ensure the system remains ‘future ready’, Critical Manufacturing, a subsidiary of ASMPT, provides the most modern, flexible and configurable manufacturing execution system (MES). Its MES employs templates, container orchestration, and DevOps (a set of practices that combines software development and IT operations). The platform runs effectively on any hardware or software configuration and can be hosted on-premises, on any cloud, or on any hybrid option. The low code system is inherently scalable and customisable, new functionality can be quickly deployed, and new sites added without large cost overheads.

At the trade fair, Hannover Messe the company is exhibiting its advanced capabilities with its products and solutions. A highly innovative solution, the Critical Manufacturing MES facilitates the adoption of Industry 4.0 manufacturing technologies with an advanced IoT platform. It provides complete, real-time visibility across global manufacturing operations, including the wider supply chain. It is designed for complete integration with new devices and legacy systems, enabling manufacturers to navigate the pathway to smart manufacturing at a pace that suits their business model. Features include end-to-end material traceability, bill of material (BOM) variation management, powerful data management tools, advanced analytics, and a complete digital twin of the shop floor to ensure total visibility of operations and performance against key performance indicators (KPIs).

Francisco Almada Lobo, Chief Executive Officer and Co-founder, of Critical Manufacturing, comments, “This technology offers manufacturers of complex and sophisticated products tremendous opportunities to increase production efficiency, enhance quality, and use data to provide deep insights into manufacturing processes and best practices while offering new levels of agility to respond to changing market demands. It is difficult to explain in words just how advanced and easy this system is which is why we are encouraging visitors to Hannover Messe to visit our stand and see for them.”

Critical Manufacturing will be at the Digital Ecosystems exhibition area, Hall 15, C13 at Hannover Fairground. On the stand, visitors will have the opportunity to discover more about the Critical Manufacturing MES with a conference space where partners and customers can learn and share experiences and insights about the MES.

The stand will incorporate a robotic arm, which will simulate an assembly station, allowing visitors to try the MES themselves by assembling a product. This will demonstrate the ease of use of the system covering work instructions, quality aspects, and intuitive dashboards. Additionally, Critical Manufacturing is one of the silver sponsors of the 15th International MES Conference, which will highlight the potential of MES for resilient manufacturing as a solution to disrupted supply chains, skills gaps and high energy prices.

“The way our MES is designed, with modules, containers and DevOps, means we are able to continually enhance its functionality. It provides ‘best in class’ performance and sets a new benchmark in ease of use,” says Almada Lobo.

Related Stories

Bharat Forge and Agile Robots sign MoU to Advance AI-Led Industrial Automation

The MoU brings together Bharat Forge’s manufacturing expertise and Germany-based Agile Robots’ AI-led robotics capabilities to accelerate intelligent automation across key civilian industrial se..

Read more

IMTEX Forming 2026: Charting the Next Chapter of India’s Metal Forming Ecosystem

IMTEX Forming 2026, Asia’s largest metal forming and manufacturing technology exhibition, is set to return to Bengaluru from 21–25 January 2026.

Read more

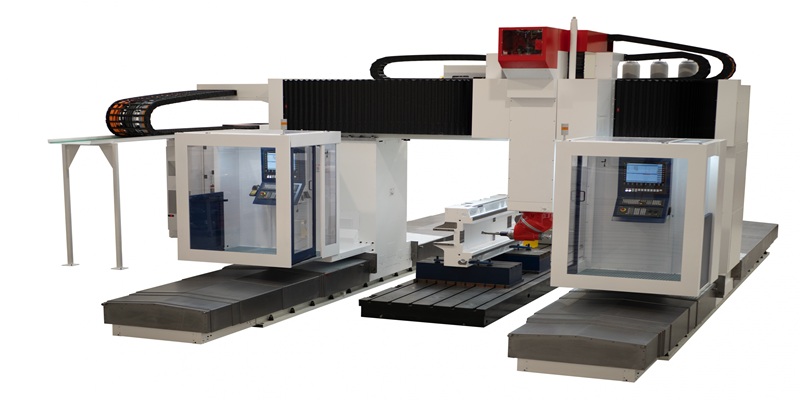

Powermill G3 HPC3 Showcases Italian Excellence in Large-scale Precision Milling

Combining robustness, precision and Industry 4.0 connectivity, the Powermill G3 HPC3 exemplifies Italian manufacturing excellence for large-scale, high-accuracy machining.

Read moreRelated Products

Compact Fmc - Motorum 3048tg With Fs2512

Meiban Engineering Technologies Pvt Ltd offers a wide range of Compact FMC - Motorum 3048TG with FS2512.

Digital Colony Counter

Rising Sun Enterprises supplies digital colony counter.

Robotic Welding SPM

Primo Automation Systems Pvt. Ltd. manufactures, supplies and exports robotic welding SPM.