Schedule a Call Back

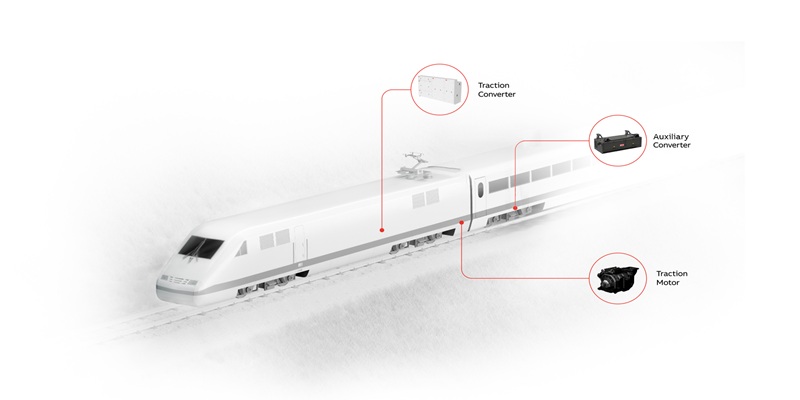

An integrated approach to create a resilient supply chain

Articles

Articles- Apr 05,24

Related Stories

India-EU FTA: How Will the ‘Mother of All Deals’ Affect Indian Industries?

The India-EU FTA offers India significant scope to expand goods and services exports through duty reductions and improved market access, though gains may initially favour the EU, writes R Jayaraman.

Read more

Expanding Industrial Base Pushes Lubes Demand

The global industrial lubricants market is expected to rise from 22.82 billion litres in 2025 to 23.61 billion litres in 2026, reaching 27.95 billion litres by 2031, according to Mordor Intelligence..

Read more

EAPL offers IoT-based products in the market: Shreedhar Kamat

In this interview, Shreedhar Kamat, Co-Founder & Chairman of Electronic Automation Pvt Ltd (EAPL), highlights advancement in manufacturing capabilities and the company’s product offerings.

Read moreRelated Products

Fanless Industrial Pc for Smart Manufacturing

CONTEC Launches BX-M4600 Series - Fanless Industrial PC for Smart Manufacturing.