Schedule a Call Back

WSN tech to deliver advanced sensing enabling Industry 4.0

Articles

Articles- Aug 27,19

Related Stories

Collins Aerospace Opens Major Manufacturing Hub in Bengaluru

New 26-acre facility to produce advanced aerospace systems for global markets.

Read more

Servotech Renewable Wins Rs 163.1 Mn Solar Project from REMCL

Servotech Renewable Power System Ltd. has been awarded a ?16.31 crore on-grid solar project by Railway Energy Management Company Limited.

Read more

Global Electronics Association Unveils Double Materiality Toolkit for CSRD Compliance

The Global Electronics Association has launched a DMA Toolkit to help electronics companies meet CSRD reporting demands with structured, sector-specific guidance.

Read moreRelated Products

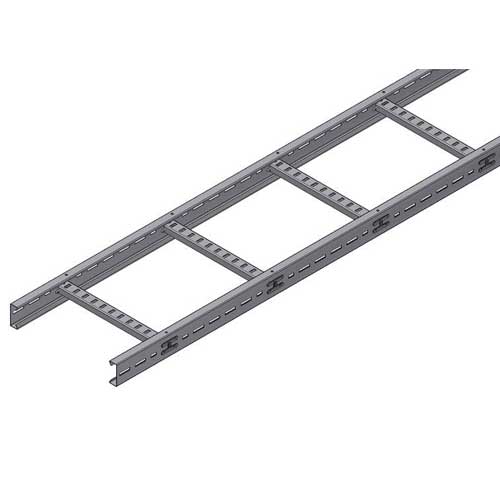

Ladder Type Cable Tray

Rama Enterprises offers a wide range of ladder type cable tray.

Wire Rope Greases

Bechem Lubrication Technology offers a wide range of wire rope greases.

ACSR Conductor and Cable

TMA International Pvt Ltd offers a wide range of ACSR

conductor and cable