Schedule a Call Back

Supreme Industries speeds development cycle with 3D printing

Articles

Articles- Oct 22,19

Related Stories

Altair announces opening of Innovation Experience Centre in Pune

The centre, located in the Altair office in Pune, will provide prospects and customers with a hands-on experience of Altair’s technology solutions – from simulation and design to high-performanc..

Read more

Apple explores 3D printing for smartwatch chassis manufacturing

This innovative technique could eliminate the necessity of carving sizable metal slabs into the desired product shape.

Read more

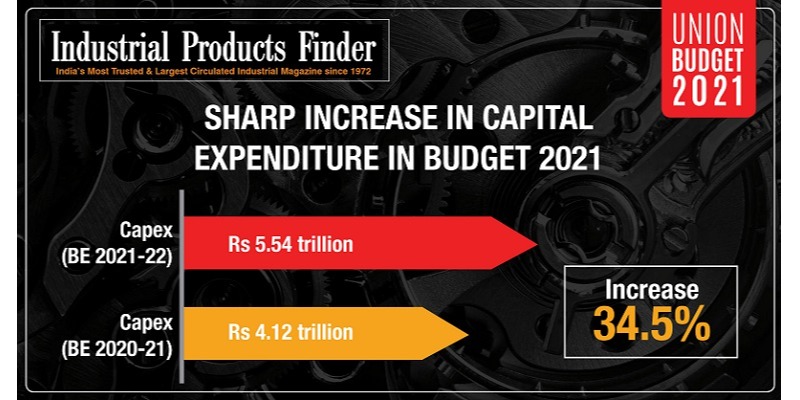

Budget 2021: Infra push to generate demand for manufacturing sector & MSMEs

By allocating Rs 5.54 trillion for infrastructure development, budget 2021-22 aims to generate demand for the manufacturing sector, especially MSMEs. Read, how companies are reacting to the budget.

Read moreRelated Products

Gravure Printing Machine

Mohindra Engineering Company manufactures gravure printing machines.

5 Colour Pad Printers

Converge Transprint Systems Pvt Ltd offers a superior quality range of 5-colour pad printers. Read more

EP-M250 Slm 3D Printer

Lodestar Innovations Private Limited offers a wide range of EP-M250 SLM 3D printer.