Schedule a Call Back

3D manufacturing brings in new opportunities for Seco Tools

Articles

Articles- Mar 29,23

Seco Tools is a leading global solution provider of metal cutting solutions for indexable milling, solid milling, turning, holemaking, threading and tooling systems. The company has benefited from additive manufacturing (AM), or 3D printing which allowed it to create products that would otherwise be difficult or impossible to manufacture. The advantages include shorter lead times, improved tool life and increased sustainability. The development and manufacture of prototypes for metal-cutting machining by means of additive manufacturing is becoming increasingly common place in the operations of Seco Tools. One of the main strengths of this manufacturing method is the possibility of making specialised customer-specific tools and solutions that are difficult to achieve through conventional manufacturing. Above all, AM technology will come into its own when producing tools that must be designed in a special way. This may involve complex geometries or other customisations to customer-specific needs.

Examples of such customisations include making the tools lighter, which improves the vibration-dampening properties, or provide them with better cooling possibilities. “By directing the coolant to hit the cutting edge at just the right place, we can significantly extend the tool’s useful life. With AM technology, coolant can be guided to locations that would otherwise have been impossible,” explained Ingemar Bite, R&D Specialist, Seco Tools, adding that AM technology is helping to shorten lead times as well. “AM allows for us to produce geometries that require less manufacturing steps, which often results in shorter lead times and thereby, faster deliveries.”

Increased sustainability

AM technology will also open up the possibility of repairing broken tools in the future, by removing dysfunctional components and printing them a new. This could, for example, involve tool components or the reuse of different types of machine-side connections. This is particularly a good idea in terms of the environment and sustainability. Another advantage with AM technology, compared with traditional manufacturing in this context, is that there is less waste of materials. Overall, not as much material is used for AM manufacturing and any leftover powder can be reused.

Additive manufacturing could thus be a time-efficient and cost-efficient method for one-of-a-kind production and prototype development. However, it could also work excellent for large-scale manufacture of standard products. Seco Tools is already manufacturing cooling clamps for its Jet stream tools through 3D printing. “The cooling clamps have a complex form with curved cooling channels and are thus well-suited to this type of manufacture,” said Ingemar Bite.

Continuous improvements

The R&D department at Seco Tools works continuously to improve the use of AM technology for the development and manufacture of new and existing products. The company is constantly looking into ways to improve its products and how to best utilise AM technology. “We like to collaborate with our customers on these efforts and to conduct tests together with them,” said Ingemar Bite. With the technology even the materials can be developed. “The materials that are currently used in AM are no different in nature than those being used in conventional manufacturing, and the technology works well with many different metals. In the future, we will add even more and superior materials, while regularly adapting our equipment and upgrading hardware and software as needed,” he concluded.

Different methods can be used for additive manufacturing, one of that Seco Tools uses is called SLM (Selective Laser Melting). Here, lasers and a bed of metal powder are used to construct the products. In an SLM machine, a roughly 20–60 µm layer of powder is spread, and then processed by a laser. This process is repeated, layer by layer. Once all the layers are in place, the excess powder is removed and the product goes into post-processing for its final form.

Related Stories

Trishul Machine Tools aims to double its capacity in 2 years: Shiva Shankaraiah

C S Shiva Shankaraiah, Trishul Machine Tools, Polygon Turning Machines, Indian Machine Tool Industry, Aerospace Manufacturing India, Electric Vehicle Components, Automation and Sustainability, India..

Read more

Seco Partners with AMRC to Drive Sustainable Machining through Data Intelligence

Looking ahead, Seco is building toward an AI-powered, automated feedback system that continuously optimises processes in real-time.

Read more

Machine tool industry’s flagship event IMTEX 2025 draws record business visitors

IMTEX 2025, during which orders worth Rs 35 billion were booked, reinforces its status as the leading global machine tool and manufacturing technology exhibition. The expo sets the stage for collabo..

Read moreRelated Products

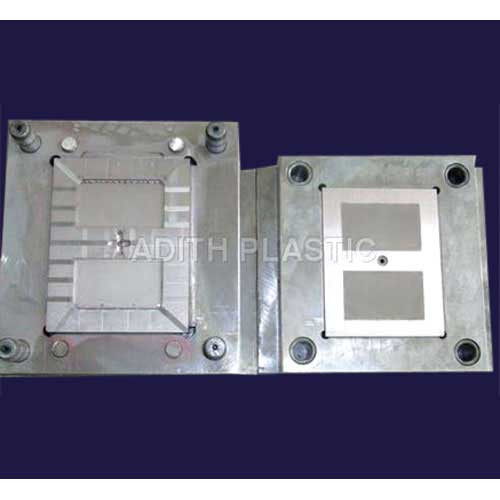

Industrial Moulds

Adith Plastic offers moulds for industrial electronic parts.

Industrial Plastic Moulding Dies

Adith Plastic offers a wide range of industrial plastic moulding dies.

Component Moulds

Innovative Moulds & Dies offers a wide range of plastic component moulds. Read more