Schedule a Call Back

Pallet System Conveyors

Pallet System Conveyors

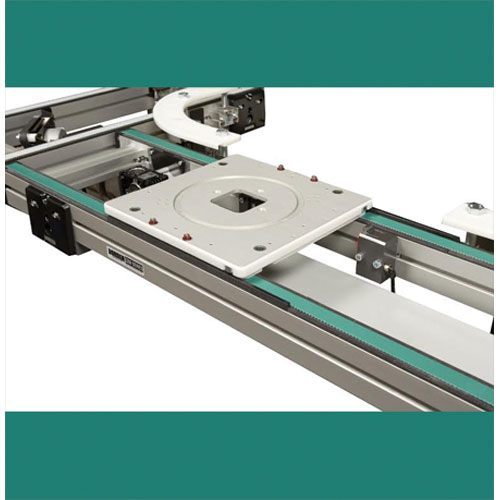

Dorner Mfg has launched its new 2200 Series Precision Move Pallet System Conveyor, the latest advancement in pallet traffic management, for the assembly automation market. With a unique pin tracking system to guide pallets through 90 turns, and a fast belt change capability without the need to remove the conveyor from the system, Dorner’s 2200 Precision Move Pallet Systems are designed to increase efficiency and reduce downtime in various assembly automation processes. Coupled with fast delivery of less than 20 days, this conveyor platform is perfect for the assembly automation, manufacturing and packaging industries. Ideal applications include automated assembly, manual assembly, product testing and inspection. The pallets on this conveyor range from 160 mm to 480 mm, giving the customer the flexibility to select the proper size to move the product. During operation, pallets move on twin dual strand timing-belt conveyors. This design provides many benefits to end users, including added load capacity in a small platform (up to 250 lbs accumulated), quick belt change without the need to remove conveyor from system, widths (160, 240, 320, 400 and 480 mm), lengths up to 7,500 mm, 20 days or less delivery time, clean room class 100 Certification on the conveyor. These engineering designs position the 2200 Series Precision Move Pallet conveyor as the go-to platform for applications in machine integration, robotic pick-n-place, precision indexing, accurate part positioning, timed conveying, and inspection.

Product & Technology News

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads