Schedule a Call Back

Nylon Pre Applied Thread Lockers

Nylon Pre Applied Thread Lockers

Glue Farm India Pvt Ltd offers Nylon Pre-applied Thread Lockers for boosting the manufacturing process. Quality control is the main reason for using thread-lockers. In the long run, avoiding warranty claims and product failures has a positive affect on a company’s reputation and sales. By understanding the mechanisms and uses of thread-lockers, engineers can choose the best options for securing joints. Around 1968, the automotive industry began using fasteners to lock and seal a screw in a carburettor. Today, thread-lockers are used in every industry. Thread-lockers can be mechanical or chemical. The two most widely used chemical thread-lockers are anaerobics and epoxies. The original thread-locker, they’re called anaerobic because they cure in the absence of oxygen and the presence of metal ions. Mechanical thread-lockers don’t bond to a fastener so much as increase friction between the mating threads. This makes it more difficult for the fastener to move. Nylon is the most common material for mechanical thread-locking. Nylon cannot be applied to fasteners in-house, but must be pre-applied in a processing plant. Perhaps the biggest advantage of preapplying thread-lockers is simply that engineers can be certain the adhesive will actually be on the fastener, in the correct amount and in the correct location. When line personnel apply liquid adhesives during assembly, the process is prone to error. The adhesive may not get dispensed on some fasteners, or it might not be applied in the right spot. Another advantage is that engineers need not worry about housekeeping or contamination issues. There is no liquid mess or sloppy run-off. Excess liquid thread-locker can be problematic, because some adhesives attack plastics. If a liquid adhesive is applied to a screw for plastic components, the run-off can harm the product. Pre-applied threadlockers will not harm plastics, which is why a growing number of electronics assemblers are using these materials in their products. Lastly, preapplying a thread-locker saves assemblers time and money. Liquid adhesives often need a primer to stick to the metal surface of a fastener. The pre-application process eliminates this step. Moreover, every drop of liquid adhesive costs money-and not just for the material itself. Assemblers also need to factor in the cost of waste, dispensing equipment, and cleaning and maintenance.

Product & Technology News

Products from Glue Farm (India) Private Limited

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

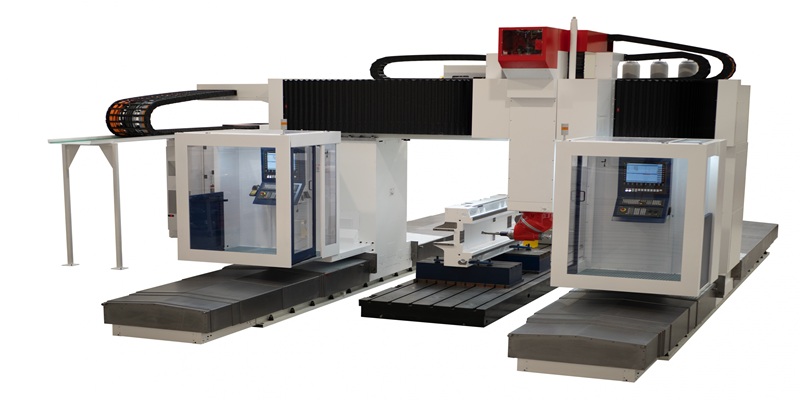

Versatile Machining Capability Through Ram Type Milling & Grinding Heads