Schedule a Call Back

Multi-Chamber Solvent-Based Vapour Degreasing/Ul Trasonic Cleaning Plants

Multi-Chamber Solvent-Based Vapour Degreasing/Ul Trasonic Cleaning Plants

Oscar ultrasonic vapour degreasing systems enhance cleaning speed and effectiveness where a high degree of cleaning is required. These systems save energy cost, labour, floor space, chemicals and solvents. The equipment mainly consists of multi-chambered tank made of stainless steel 316 housed in an elegantly painted MS cabinet. Ultrasonic generator is fitted at the bottom of the cabinet and the equipment is provided with a state of the art control system which is easy to operate. The components are first dipcleaned in the precleaning chamber for removal of gross contaminants, followed by vigorous ultrasonic agitation. Then the components are held in vapour chamber for vapour rinsing and drying. The pure vapour condenses on the components, dissolving the grease and soil. As the components reach the vapour temperature, the condensation stops and components come out clean and dry. For efficient solvent recovery, water is circulated in the condensation coils. The system comprises of two, three or four-chamber tanks, depending upon the level of contamination and the degree of cleaning desired. Units are also available with direct refrigeration cooling systems, distillation plants, filtration systems and fume extraction systems. The systems use trichloroethylene and perchloroethylene as degreasing egents. These chemicals do not affect the ozone layer.

Products from Oscar Ultrasonics

Ultrasonic Cleaner (Microclean)

Water Based Ultrasonic Cleaning Systems

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

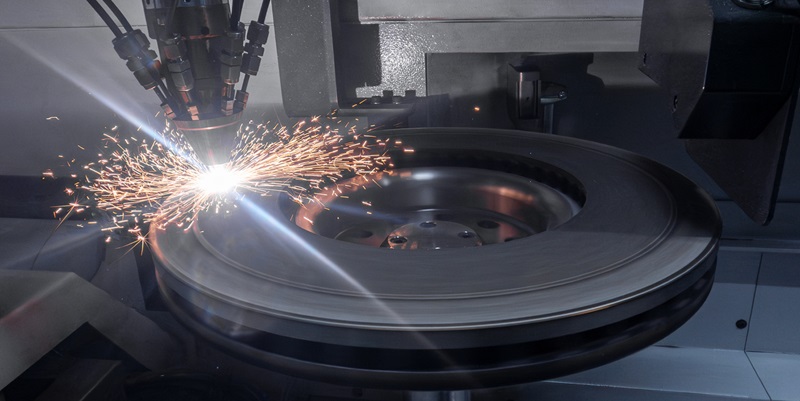

Versatile Machining Capability Through Ram Type Milling & Grinding Heads