Schedule a Call Back

Aqueous Washing Machine

Aqueous Washing Machine

The Ultraseal Caskade is a new kind of high volume, ultra efficient aqueous washing machine for industrial components. It gets thousands of components squeaky clean and dry, inside and out, every hour, at a fraction of the cost of solvent based cleaning systems. The components are slowly rotated under a waterfall of hot filtered washing solution before being subjected to an optional vacuum dry cycle. The energy from the weight and volume of washing media passing over and through the components produces an exceptional level of cleanliness in a short processing time. The application of vacuum, immediately following the washing and draining cycle, ensures that any residual moisture or water left on the components (even that retained in small deep blind tapped holes) is evaporated completely, leaving the parts clean and dry. Components can be accommodated in standard process trays or tote pans that can be modified to hold, separate and protect machined surfaces as required. This creates the opportunity to transfer high volumes of finished components in their trays from the machining line to, and through the Caskade washing machine without handling the individual parts. Standard features: hot Caskade rotational wash/dry module fabricated from stainless steel; fast process times with rotation drain minimising chemical carryover and consumption; impact Caskade washing action, PLC with variable operator control settings and process cycle selection; fully enclosed font load machine; electric heating of wash solution with adjustable temperature control; manual pneumatically controlled opening/closing of vertical door with safety interlock; roller conveyor along front of machine for transfer of component baskets into process chamber; automatic water top up of washing solution; and low level alarm to protect heaters and process pump, steam extraction. Optional items: vacuum dry, hot air dry, oil separator, in line filtration of washing media, automatic dosing of washing chemicals, additional tanks to accommodate other surface treatment requirements, (e.g., chromating, iron phosphating, etc), variable size of process chamber, and ultrasonics.

Product & Technology News

Products from Ultraseal (India) Private Limited

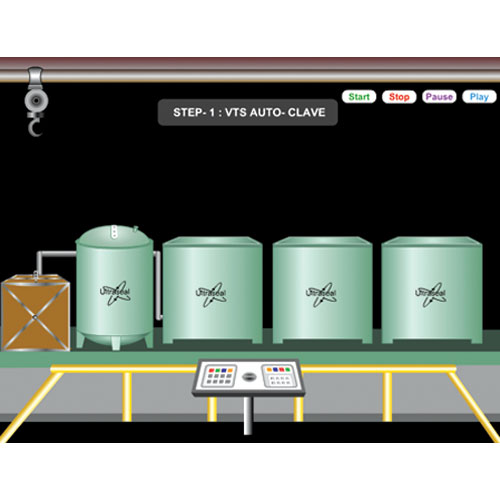

VTS Rotational Impregnation System

Vacuum Impregnation Plant, Fully Automatic

Aqueous Washing Machine, Ultraseal Caskade

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads