Schedule a Call Back

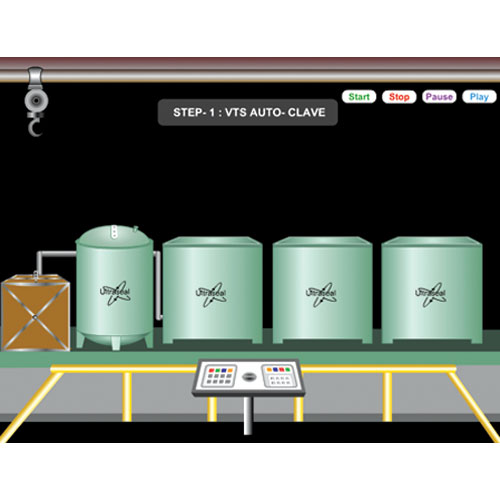

VTS Rotational Impregnation System

VTS Rotational Impregnation System

Ultraseal (India) Pvt Ltd offers the Ultraseal VTS (Vertical Transfer Systems) Rotational Impregnation System.

Benefits of VTS rotational impregnation system, When compared to conventional Resin Transfer System (RTS) are:

- Increased production throughput – Process cycle times faster

- Reduced initial fill sealant volumes – Substantial savings in the cost of the initial fill of sealant

- Reduced maintenance costs – Simple mechanical construction with no complicated control system for transfer of sealant between storage tank and process chamber

- Reduced floor space – No separate sealant storage tank required

- Reduced length of overhead monorail – Monorail does not have to run above a sealant storage vessel

- Efficient degas system – Ensures sealant is correctly conditioned for optimum sealing performance

- Efficient refrigeration system – Controls temperature of sealant within specified operating process parameters