Schedule a Call Back

Laser Systems for Welding, Cutting, Drilling, Etc

Laser Systems for Welding, Cutting, Drilling, Etc

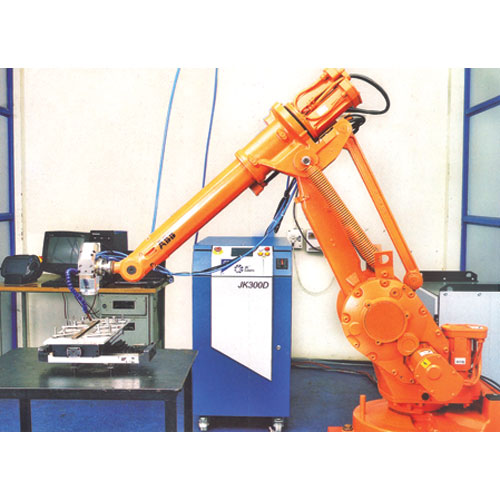

Optilase Techniks (I) Pvt Ltd offers Laser Systems for Welding, Cutting, Drilling and Marking. Established in the year 1994, the company provides laser solutions to industry backed by 25 years of experience and expertise in laser processing field. It has an installed base of more than 30 lasers working in the field. The company offers lasers from GSI, robots from ABB and custom built CNCs depending on the application.

Welding (0.1-6 mm thickness): Laser welding is usually done without filler metals so parts need to have good fit-up with a gap less than 15% of the thickness of the thinnest component. Weld heat input and weld shape can be controlled with laser parameters and optics to generate conduction-mode welds, penetration-mode welds, and keyhole welds.

Cutting (0.1-10 mm thickness): Cutting requires that the laser beam is focused by a lens to a small focus spot typically in the 25-100 µm diameter range for fine cutting and 100 µm to 30 µm range for thicker section cutting. Coaxial gas is delivered just above laser focus by a nozzle that surrounds the converging laser beam to keep the optics clean and improve the cutting process by pushing the vaporised and liquefied material out through the kerf.

Drilling (0.5-20 mm thickness): Percussion drilling means adjusting the laser's focus spot size to determine the hole size. There is no relative motion between the laser beam and the part during the drilling process. Debris coming out of the hole can interfere with the end of a long duration pulse so breaking it up improves efficiency and reduce drilling time. Using a pulse shape with a lower peak segment at the beginning can create a hole that has less initial bell-mouth.

Hardening: High power heat source produced by a laser beam is ideal for surface modification.

Heating without melting: Commonly known as heat treatment. This involves solid-state transformation, so that surface of the metal is not melted. Both mechanical (hardness, abrasion, resistance, etc), and chemical

properties, (corrosion resistance, etc), can often be greatly enhanced through the metallurgical reactions produced during these heating and cooling cycles.

Product & Technology News

Products from Optilase Techniks (I) Private Limited

Hydroforming & Body Cutting Systems

Laser Scribing for Chip Control

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads