Schedule a Call Back

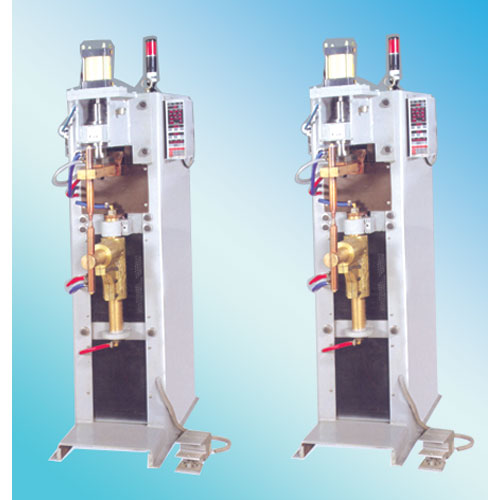

Constant Current Resistance Welding Controller

Constant Current Resistance Welding Controller

The constant current resistance welding controller with in-built monitor function helps in welding automation in terms of detection of faults and monitoring of the process. By using welding data logger (fcom_v2.0) software, welding data can be collected from each controller at real time and the collected data can be stored in Excel file on computer. One PC can be linked to maximum 32 units. Weld current data and scheduled data can be requested to each controller and can be seen and printed. Weld schedule can be changed from the PC. Even monitoring for welding defects; time and weld current data can be checked easily at real time. Opto-isolated RS485 converter (option) is installed in the controller. A PC can be connected to the controller by 2 electric wires and the maximum length could be 1.2 km. Advantages: assures 100% certainty of welded spots, with non-conforming spots alarmed instantly; supplies stable welding current by secondary constant current method; networking of up to 32 machines (optional); p

Products from Kirti Pressings Private Limited

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads