Schedule a Call Back

Solution For Condensate Handling In Hydraulic Hot Press

Solution For Condensate Handling In Hydraulic Hot Press

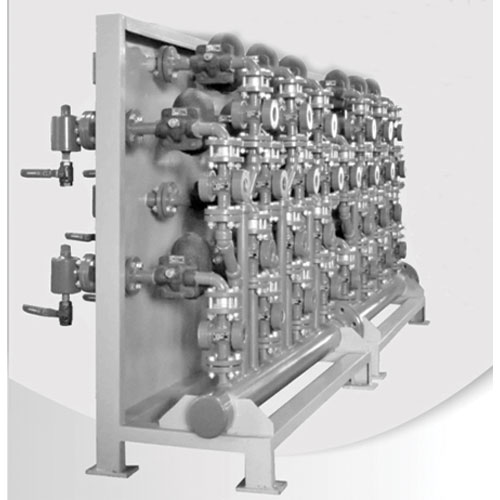

Indo Anushka offers Module-HST, the ultimate Solution for Condensate Handling in Hydraulic Hot Press. Hot presses traditionally are provided with a single large trap installed on a common larger sized condensate header for trapping of steam and draining of condensate. The large header is connected through piping from the different platen plate condensate outlets. This kind of group trapping of all platens results into flashing of condensate in the larger condensate header before the trap and retaining of condensate in the platen plates. This gives rise to the possibility of under prepared laminates or spots on laminates resulting into rejects. Now, in order to effectively remove this condensate from the platen plates and to get good quality laminates without rejects, a huge amount of steam is continuously lost by keeping the trap bypass partially open throughout as well as keeping the trap bypass fully open during the short flushing cycles when after a drop in the platen temperature the pressurized steam itself is used to forcefully remove the condensate from the platen plates through open bypass. Module-HST is a complete retrofitable, independent and wholesome steam trapping solution for hot presses.

Product & Technology News

- Independent And Wholesome Packaged Condensate Handling Solution For Hot Presses Designed Specifically For Hot Presses

- Designed To Remove All Condensate Water From The Platens But With No Steam Blowouts

- Completely Stops The Practice Of Blowout In Hot Presses

Products from Indo Anushka Steam Technologies

Modular Water Heating Systems MWHS

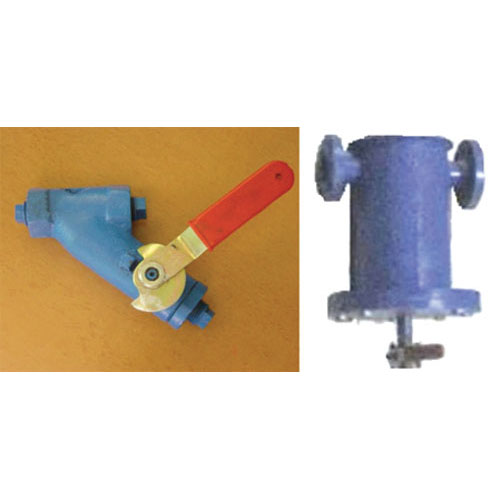

Strainers with Inbuilt Blowdown Valves

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads