Schedule a Call Back

Cut-To-Length Line/Flying Cutter CNC

Cut-To-Length Line/Flying Cutter CNC

Flying Curler CNC AC-2002 is a microprocessor based control system with CNC architecture for closed loop position control and speed synchronisaoon for cut/shear control in cut-to-length lines. The built-in PLC offers a tremendous flexibility of incorporating the machine specific logic. The controller measures the position of the moving slide as well as of the rolling sheet with micron precision and synchronises the slide speed with the speed of the moving sheet, thus providing for the flying cut/shear feature. This provides the machine with flexibility, higher speed of operation and eliminates additional processes like sag provision-tension control, etc. The flying shear starts at a proper time and accelerates to match the speed of the line and the programmed length of the sheet. The final cutting/ shearing takes place at the programmed length. The shear then returns to the home position and gets ready for the next cut. The operator panel provides for entering the user programs. Each user program contains the total number of cuts, length to cut, speed of operation and other parameters as required for the synchronisation of peripherals such as decoiler, stacker, puncher, etc. The display shows the machine status position, number of cuts, program number, cut number, etc. It also provides for the display of messages and alanns for the complete system.

Product & Technology News

Application areas are: shearing/cutting/slitting rnachines, cut-to-length lines, paper and tape cutting machines, transfer lines, presses and press brakes with synchronised materials handling transfer lines.

- Closed loop position control with CNC precision

- Synchronisation with peripherals such as decoiler/ coiler, slacker, puncher, etc

- Industrial standard operator panel with completely sealed membrane keyboard and LED display

- ±10 V, 12-bit analogue output for use with servodrive

- Interface for operator pushbuttons, emergency off and other machine interlock limit switches, etc

- User programming through operator panel for cut positions and machine data

- Multiple program storage facility

- Battery backup for memory; rotary encoder/linear scale interface for 5 V, differential line driver/TTL outputs

- Absolute or incremental positioning

- DIN standard rack enclosure, thus expandable

Products from Asia Automation Private Limited

Air Jet Weaving Machine Controller

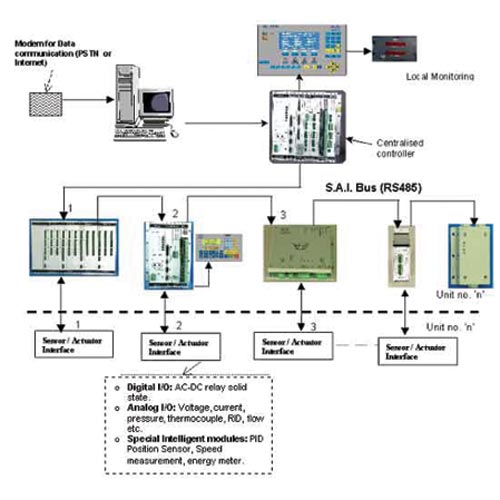

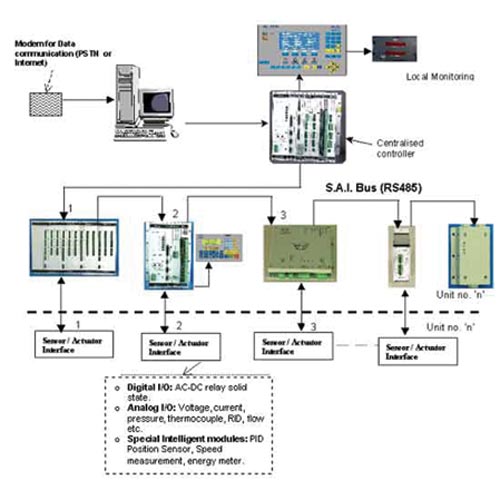

Sensor Actuator Interface Control System

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads