Schedule a Call Back

New Coupling of EEC One and EPLAN Pro Panel

New Coupling of EEC One and EPLAN Pro Panel

Standardisation, re-utilisation and automation are gaining importance in control cabinet build. The coupling of EEC One and Eplan Pro Panel shortens development times and leaves room for innovations. Starting with Version 2.4, EEC One automatically generates mounting panel layouts.

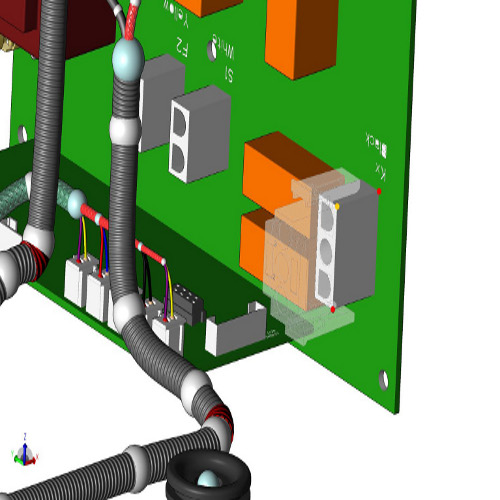

EEC One enables the automatic generation of electrical or fluid power schematics based on standardised macros and components. Eplan is now expanding this technology to also include control cabinet engineering: mounting panel layouts will soon also be automatically generated. Standardisation and automation produce significant gains in efficiency. At the same time, the degree of re-utilisation increases substantially. At the Hannover Messe 2014, users got a first glimpse of the software, which will soon be available with the new Eplan Platform 2.4. Eplan Pro Panel, the 3D solution for virtual control cabinet and switchgear construction, is an elementary component of the Eplan Platform. In the shared component database, data is available for Eplan Pro Panel and is thus also accessible in EEC One. For instance, the 3D macros required, as well as the pre-assembled standard layouts for mounting plates, will from version 2.4 also be utilised in EEC One. Mounting plate configuration is specified via variables or values. Subsequently, the components are assigned to the appropriate mounting rails and precisely positioned using placement options with predefined spacing.

The generation of new 3D mounting layouts in EEC One is based on selecting the component macros as well as on specification of placement rules and references for each layout. Everything is completely automated and happens at the push of a button. The components are placed on the mounting rails in their assigned positions. “This automation reduces the effort of, on the one hand, positioning components manually and at the same time increases the control cabinet’s quality and improves documentation,†says Thomas Weichsel, Product Manager for Eplan. Transcription errors or the use of outdated schematics are strictly avoided. The complete mounting layout is bored, milled and wired virtually and then integrated into the manufacturing process via Eplan Pro Panel Professional. Examples include the coupling of machinery for the mechanical processing of control cabinet components, fully automatic machines for conductor assemblies or automated wiring of equipment. With additional options – for instance, the Eplan Pro Panel Copper expansion module for the design of individual copper rails and flexible power distributors – preconfigured and automatically generated layouts can be expanded and tailored to specific orders.

Eplan continues to increase efficiency in engineering processes with this timesaving automated method of operation. The coupling of EEC One and Eplan Pro Panel Professional has generated new potentials of standardisation, re-utilisation and, ultimately, automation. This results in reduced time-to-market and more freedom to take on new projects and develop new innovations.

Product & Technology News

Products from Rittal India P Limited - EPLAN Division

Wire Harness Engineering: From Schematics Through To Production

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads