Schedule a Call Back

LM Accessories - Locknuts, Locking Elements, Couplings and Greases

LM Accessories - Locknuts, Locking Elements, Couplings and Greases

Amcats offers LM Accessories – Locknuts, Locking Elements, Couplings and Greases. Precision locknuts, couplings, locking elements and greases are part of our Linear Motion accessories line-up.

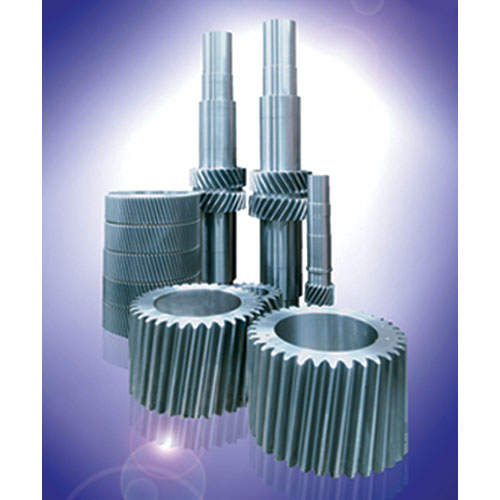

Precision Locknuts

YHB is the leading manufacturer of precision lock nuts and locking elements from South Korea. Precision lock nuts are used with ball screw support bearings, spindle bearings, pulleys, in gearboxes, etc. Locking elements are used for applications like pulley, gear, flywheel, cam, lever, etc. These are widely used by all OEMs of CNC machine tools. They eliminate the need for lock washers, double nuts, keys and key way working for shafts. So assembly becomes easy.

YHB range of lock nuts covers radial locking, axial locking and angular locking types. So these can be used for almost all types of applications. The different types available are:

|

ZM |

|

|

SLN |

|

| MSR |

|

|

YHB |

|

| YN |

|

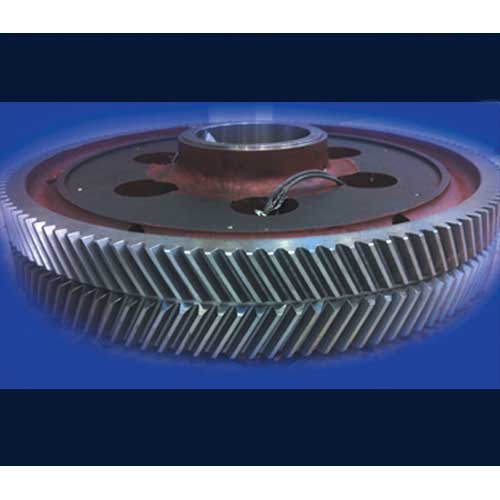

Locking Elements

Locking elements are used when high transfer torque is required while connecting shaft and boss. The locking elements are available for shaft diameter from 14 mm to 480 mm. It covers high transmissible torque ranges also. These items are available from stock.

| Locking Element SWLE | |

| 300 Type | Where large scale key is required and radial work is not allowed |

| 100 Type | For Medium High torque |

| 200 Type | For High transfer torque |

| 200A | For High Transfer Torque + Precise positioning |

| 200B | Precise positioning + High transfer torque |

| 200C | For Ultra high transfer torque (E.g. Large scale pulley) |

| 200D | For Medium high torque. No shaft hub axial movement |

Â

Â

Â

Â

Â

Couplings

We offer an extensive range of industry's most technically advanced backlash-free servo couplings and magnetic couplings. The basic models are metal bellow couplings, servo-insert couplings, safety couplings and magnetic safety couplings. All are designed to dramatically diminish downtime and production costs. Most of our offerings are set apart by technological benefits that are not available from any other company.

The broad line up of in-stock products ensures right solution for each and every manufacturing challenge. Customized Couplings can be designed on request. Every coupling type is available in corrosion-proof stainless steel for pharmaceutical and food industry. These couplings are widely used in CNC machines, packaging, textiles, printing, injection moulding, robots, material handling, bottle filling and cap-tightening machines.

Backlash free metal bellows couplings provide today’s high-speed, automated manufacturing applications with servo quality stiffness, low inertia and an exceptionally long equipment life.

ADS servo insert couplings with 64D shore hardness inserts, offer high torsional stiffness and dampening, allowing CNC controls to optimise maximum servo loop gain without resonance. This results in shorter cycle times.

The specially designed curved jaw with close tolerance and 64D shore hardness insert meets CNC machine requirements, and costs 50% less to make the machines more competitive. These couplings are also available with balancing for spindle application in 20,000 RPM.

Magnetic couplings are used for chemical pumps, refrigeration compressors, fuel cells, non contact power transmission, high speed test stands and packaging, bottle filling and cap tightening machines and in food industry machines.

Greases

Lubrication is necessary when using LM systems. Without lubrication, the rolling elements will wear out faster and shorten service life. The lubricant that is used needs to satisfy various requirements like low friction, high wear resistance, high thermal stability, high oil film strength, anti-corrosion, etc. THK provides greases for different purposes with the above requirements fulfilled.

- AFA – For long Service Life

- AFB-LF – All purpose Lithium based

- AFC – For High Speed/ Micro Vibration

- AFE-CA – Urea based Clean Environment grease

- AFF – Lithium based Clean Environment grease

- AFG – For tackling Ball Screw heating

Product & Technology News

Products from Amcats Private Limited

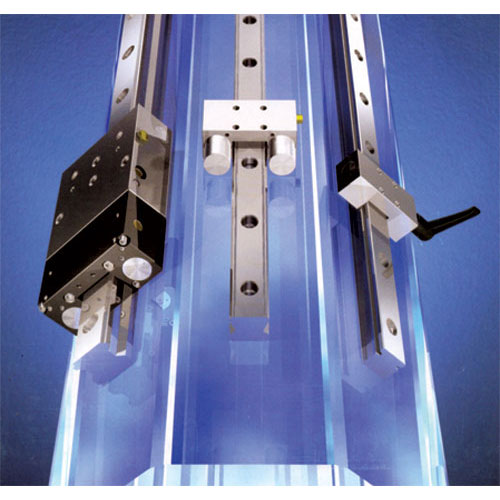

Clamping & Braking Elements For Linear Guides

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads