Schedule a Call Back

Residual-Oil Monitoring System

Residual-Oil Monitoring System

Compressed air contaminated by oil is the horror of every compressed-air user. Depending on the use, there is a risk for production plants, the environment, or even for health. In the majority of cases, a certain residual oil content cannot totally be avoided with standard applications. The compressed air classes defined in ISO 8753-1 offer an orientation for the assessment of the compressed-air quality. However, it is important for the user to be informed about the concentration at all times. Samplings and laboratory evaluations are complex and expensive and, in addition, represent nothing but a snapshot of a past moment in time. The OilControl monitoring system from BEKO Instruments allows permanent oil-content monitoring of the flowing compressed air. The quality of compressed air can thus be monitored online for the very first time by measuring the residual oil content. Measurement is carried out by means of an ion-exchange method. The sensitivity of the sensor guarantees early detection of an increasing oil content, resulting, for example, from defective filters. This helps to successfully avoid consequential damage to machines and products. Compressed air as a production medium therefore gains in reliability, and the user avoids unnecessary expenses, as the purchasing costs of an OilControl monitoring system are significantly lower than the follow-up costs resulting from a production stop.

Product & Technology News

Products from BEKO Compressed Air Technologies Private Limited

Catalyst for Compressed Air Treatment

Compressed Air Dryer, Drypoint RA

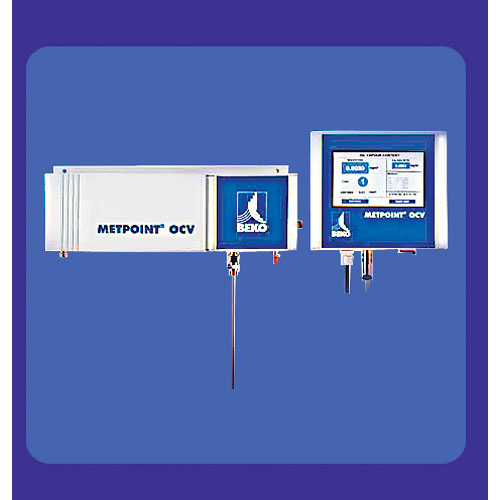

Oil Monitor For Compressed Air, Metpoint OCV

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads