Schedule a Call Back

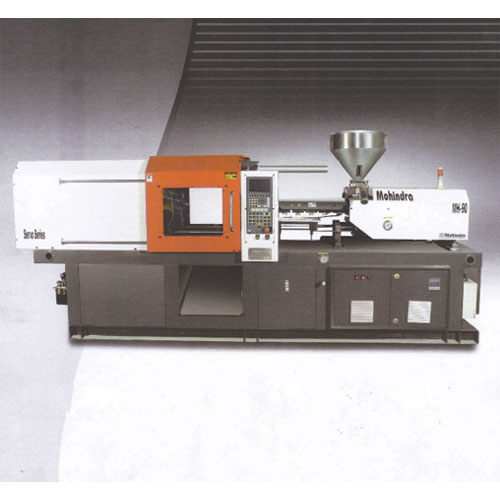

Injection Moulding Machine, Fully Automatic

Injection Moulding Machine, Fully Automatic

Mohindra Engineering Works offers a fully automatic, vertical Injection Moulding Machine. The injection comprises of nitrated screw and barrel and is powered by a high torque, low speed hydraulic motor. It is equipped with 5-stage injection speed and 4-stage holding pressure control. Clamping is by hard chrome-coating alloy steel tie bars, five-point double toggle clamping mechanism and automatic mould height adjustment. The screw is of well-known brand better hardened for long life, dedicated to PET/PC/PS/PVC and thermoset material. The variable displacement pump is of low noise, reasonable hydraulic control structure design and high integration. With high stability, it offers 30 to 70% energy saving compared with fixed pump under the equivalent volume of work. The hydraulic system is fabricated from imported hydraulic components. Servo energy-saving system adopts servo motor composite structure of oil and electricity for better performance – high precision, high response and low noise. The control system adopts professional controlling system of inject moulding and large screen display for high definition. Control unit: PID temperature controller; linear transducer for clamping ejecting and injection stroke control; timer or stroke control for injection; alarm light; self diagnostic; and digital storage for moulds. Mohindra Engineering Works, established in 1994, is a pioneer manufacturer of high precision plastic injection moulding machine and Bakelite moulding machines in various models.

Product & Technology News

Products from Mohindra Engineering Works

Hydraulic Special Purpose Machine

Hydraulic Bakelite Compression Moulding Machine

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads