Schedule a Call Back

Ductile Iron (SG Iron) Casting

Ductile Iron (SG Iron) Casting

Ductile Iron Casting is finding increasing application for a very wide range of components in which it can replace gray iron because of its superior properties. Ductile iron can be used to replace many more expensive components previously made in wrought or cast steels or other metals because of its higher strength-to-weight ratio, lower damping capacity, better machinability, and better castability

Advantages of Ductile Iron Casting

Ductile Iron Casting provides Higher Tensile Strength, Less Deflection Under Load Conditions, No Straightning Required in Most Instances, No Problems With Hot Tears and Cracks, Good Machinability, Easier Feeding of Difficult Designs...

Product & Technology News

Typical Applications for Ductile Iron Casting

Ductile Iron Casting is particularly well suited for Valves, Pump - Gears and Rollers, Spring Hangers, Suspension Parts, Wheel Hubs, Bearing Caps, Hardware, Universal Joints, Threadless Connectors and Flanges, Various Automotive and Agricultural Items.

Ductile iron gears have performed well in non-critical engineering and agricultural applications, but austempered ductile iron offers a combination of strength, fatigue properties, and wear resistance that makes it of great interest for heavy engineering and automotive gears - applications in which the use of austempered ductile iron is likely to increase. Many new engineering components are likely to be amenable to design with ductile iron.

Products from Heattrans Equipments Private Limited

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

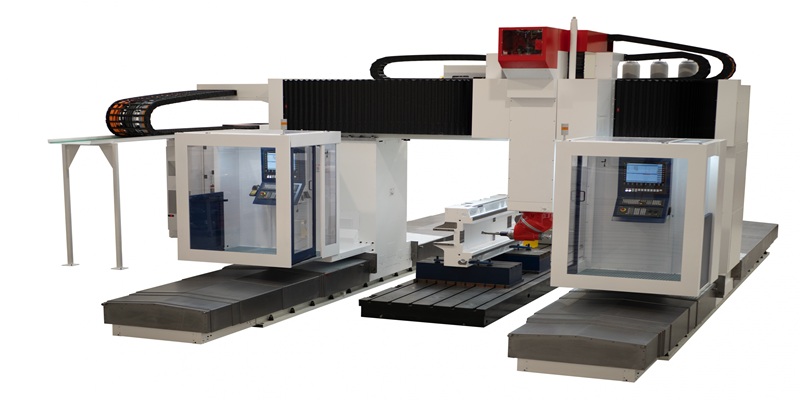

Versatile Machining Capability Through Ram Type Milling & Grinding Heads