Schedule a Call Back

Centreless Bar Peeling Machine

Centreless Bar Peeling Machine

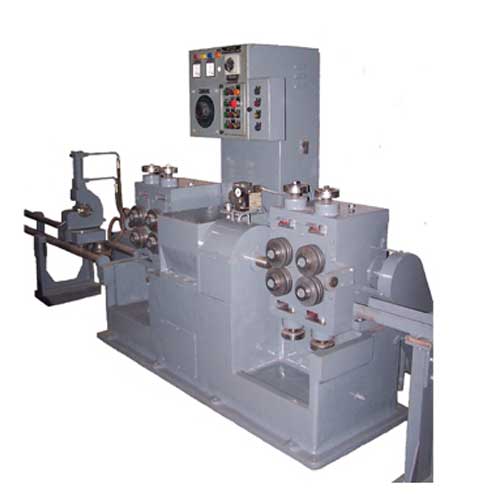

Bhambra Engineering Works offers Centreless Bar Peeling Machine, TM-15. The Capacities of Peeling is from 07mm to 15mm diameter.

Working Principle:

The bar to be peeled is supported between an entry guide and steady rollers. The cutting tool is mounted in a cutter head, which in turn is fixed on a revolving spindle. The bar to be turned in moved by feed rollers against the revolving cutter head.

Technical Specification & Construction of the machine:

- Head Stock:

This is a rigid casting containing a revolving main spindle driven through ‘V’ belts and shifting gears from the main motor. A cutter head is fixed to the main spindle. The head is designed to hold a cutting tool and also rollers for polishing the work. The spindle speeds can be varied by means of changed gears. - Feed Gear Box:

This is also a rigid casting. The feed rollers are operated by a motor through ‘V’ belts and worm gear. The rollers feed the bar against the revolving cutter head. The feed rate of the bar is varied through dimmer stat. All the shafts are mounted on bearings. Worm and worm gears are oil lubricated and bearings and gears are grease lubricated. - Bed:

This is a cast iron base on which the feed gear box and head stock assemblies are mounted. The main motor is fixed on the left rear wall of the bed and feed gear box motor on the right rear side of the bed. Passage is provided for the chip and coolant flow. - Cutter Head:

This is a cast steel part. Two thiffs, three polishing rollers (HCHCr) and one carbide tool are fixed. The entire assembly is bolted to a face plate which in turn is threaded (clock – wise) to the main spindle. The cutter head will rotate with the main spindle while the bar is fed longitudinally. - Coolant System: Constant flow of mineral based cutting oil is splattered on cutter head to cool the tool and rollers.

- Input & Output Carriages:

For supporting and preventing the rotation of the bar, input and output carriages are provided with the machine.

The company also offers other models such as TM-45, TM-75 and TM-100.

Product & Technology News

| Model: TM-15 | KW / RPM / Volts |

| Motor for Cutting Head | 11 KW/1500 R.P.M./220 V D.C. |

| Motor for Feeding Gear Box | 2.2 KW /1500 R.P.M/220 V D.C. |

| Coolant Pump Motor | 0.18 KW./2800 R.P.M/415 V A.C. |

| Hydraulic Power Pack Motor | 0.75 KW./1500 R.P.M/415 V A.C. |

| Control Panel | Centralized operational console with interlocks |

Products from Bhambra Engineering Works

Section Straightening Machines

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads