Schedule a Call Back

Copper Bar Punching Machine

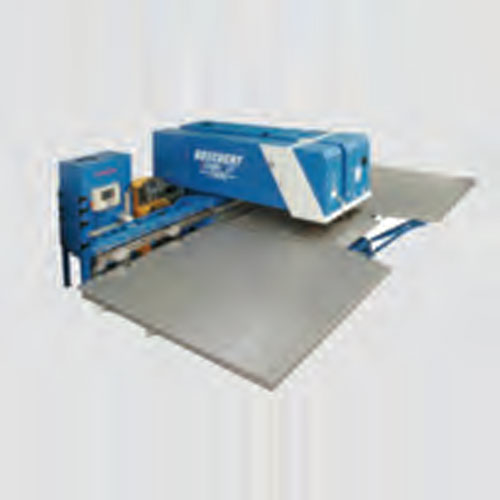

Copper Bar Punching Machine

For the efficient punching of copper bars Boschert have developed a new machine concept to solve the problems of copper processing in the renowned Boschert quality. The hydraulic material clamping ensures exact positioning prior to punching. Material feeding takes place with a clamp, which ensures complete processing with a minimum of waste. Quick tool change is made possible by means of the tool cassette that is extendable from the machine housing. On the picture are two punching heads and one cut-to-length shearing unit. Model CUWK-1 punching machine, adapted to the requirements for copper processing, can work copper bars up to 15 feet, 8 inch wide and 1/2 inch material thickness. Proven graphic software supports quick programming with operator friendliness. Quick tool change is made possible by means of the tool cassette that is extendable from the machine housing. Material feeding takes place with a clamp, which ensures complete processing with a minimum of waste. This feeding unit is supported on two linear guides and, with a roller-ball spindle and an AC servomotor, guarantees a repetition accuracy of plus/minus 0.003 inch. The hydraulic material clamping ensures processing without bending of the finished parts, even when the punching, as shown here, takes place on the outer edge.

Product & Technology News

Products from Techno Crafts

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads