Schedule a Call Back

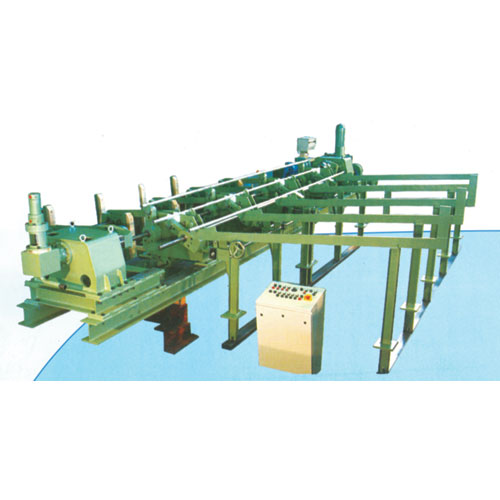

Tube Mill

Tube Mill

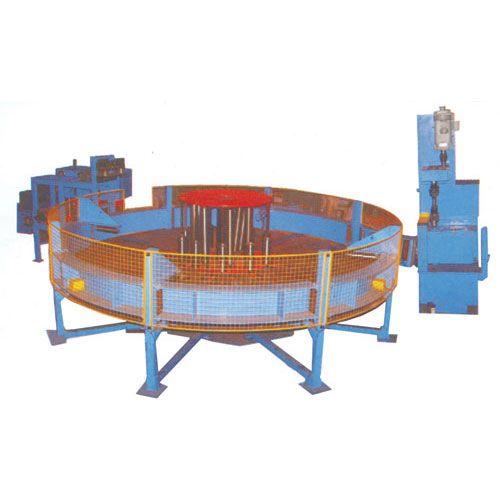

Rollform Equipment is India’s leading manufacturer of equipment for pipe and tube production, with a complete range of pipe and tube mill machinery for structural, automotive, boiler, API and other applications; and HF welders and motion control systems all manufactured under one roof in collaboration with M/s Manfred OLK Technical Consultant, Germany. While the software for tube mill roll design is sourced from data M, Germany, all the equipment is meticulously designed with the help of pro-engineer software from USA. The company has the distinction of being a leading supplier of on-line NC flying saw cold cut off for burr free cutting of tubes in India. It has also tied-up with M/s Simec s.r.l. Italy, the world’s leading supplier of stationary cold saws for indigenous production of such machines. The Tube Mills are based on German design and incorporate concepts, which make them robust, precise, user friendly and maintenance free. They include a fully mechanised entry line including hydraulic shear and welder and fully automatic horizontal spiral accumulator for totally stress free strip accumulation.

Product & Technology News

- Highly efficient and accurate helical reduction and distribution gearboxes to drive the mill, which reduces power consumption as compared to worm gearboxes

- Robust 2/3 roll type squeeze roll assemblies for a precise control of weld parameters and to reduce the size of rolls for enhancing HF welder efficiency

- Fin roll type seam guide unit is installed close to the squeeze roll to enable a precise control of V-angle

- Special driven shaping stands are used in sizing mill for precise and gradual formation of heavy hollow sections

- An NC flying friction/cold cut off system is installed in all types of mills, to provide a computerised, programmable and accurate cutting operation, which is user friendly and maintenance free

Main features

- Fully mechanized entry line

- Line speed up to 120 m per min

- Quick change cassette type design

- Driven shaping stands for sections

- Higher range of I/D ratios

- OD accuracy on tube up to ±0.04 mm

- Length accuracy on tube up to ±2.0 mm

- Burr-free cut ends

- Very low levels of maintenance and bearing consumption

- Special roll design to reduce cold working on tubes hence reducing power consumption on mill

Products from Rollform Equipment Private Limited

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

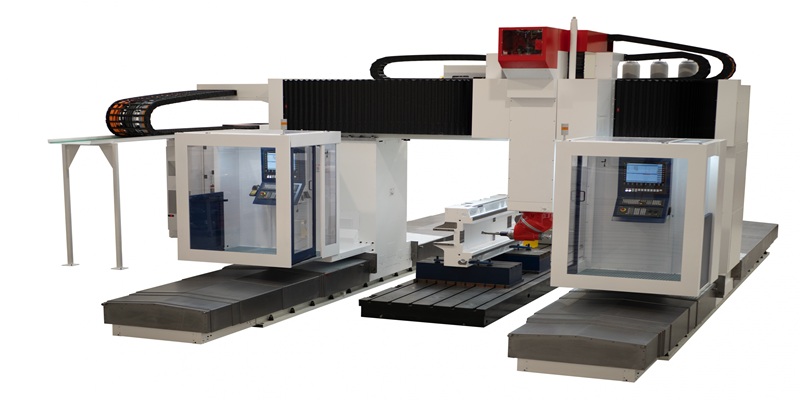

Versatile Machining Capability Through Ram Type Milling & Grinding Heads