Schedule a Call Back

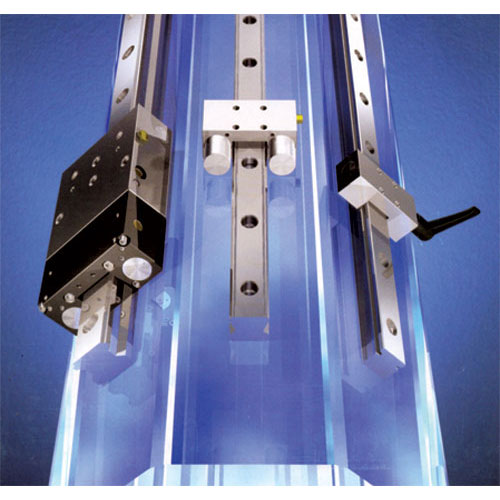

THK LM Guides

THK LM Guides

THK's creative ideas and unique technology made the company worldwide pioneers in the development of the Linear Motion (LM) Guide mechanism. Today, the LM Guide is an indispensable component of mechanical and electronic systems in a wide variety of industries whether it is Machining centres and grinding machines used by the Machine tool industry or an X-Ray machine and MRI used in the Medical field. The THK LM Guide is used everywhere from huge skyscrapers for earthquake protection to positioning in optical instruments; used in creating Megastructures and Nano ICs.

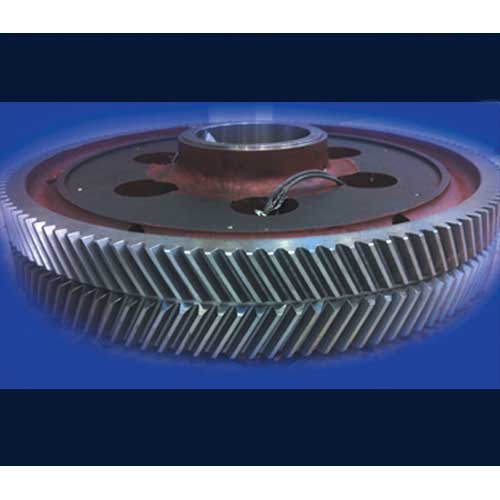

Caged Ball Technology

High levels of noise, short service life and the inability of usage at high rotating speeds led to the development of the ball cage in ball bearings. These ball bearings with cage were able to demonstrate long service life despite the number of balls being fewer than packed ball types, and evolved significantly so that they were able to be used in a wide range of applications.

THK has developed a similar technology for the LM Guide called the Caged Ball Technology and Caged Roller Technology where the balls don’t touch each other but are separated by the cage structure which keeps the balls aligned.

Features of Caged Ball Technology

Â

-

Quiet Operation - Interference noise between balls is eliminated by the ball cage resulting in quiet operation.

-

Orderly Ball Movement - Balls are held by the cage in the form of a belt. They are aligned uniformly and move in a circulating manner. There is no skewing of the balls, while sudden variations in friction are also eliminated.

-

Excellent High-Speed Performance - The use of ball cages eliminates generation of heat caused by friction between balls resulting in excellent high-speed performance.

-

Grease Holding Structure - Grease pockets are provided consecutively over the entire ball circulating path to constantly lubricate the balls enabling long-term, maintenance-free operation and Long Service Life.

Â

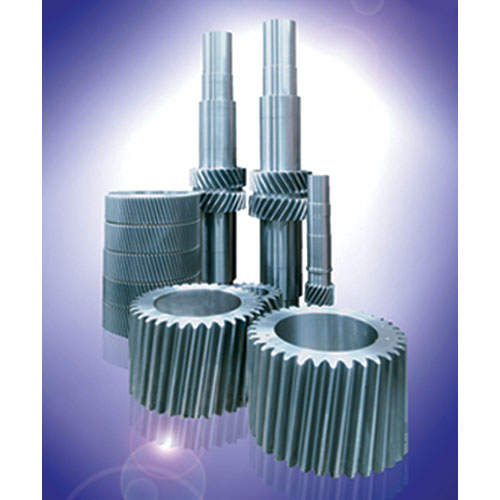

Types of Guides

THK has developed a variety of LM Guides to satisfy the various applications and scenarios under which they are used. But they can be broadly classified into Caged Ball and Caged Roller type, Full Ball type and Cross Roller Type LM Guides.

| Caged Ball and Caged Roller Guide | |||

|

SHS

(HSR) |

|

SSR

(SR) |

|

|

SNS

(NRS) |

|

SNR

(NR) |

|

|

SHW

(HRW) |

|

SRS

(RSR) |

|

|

SCR

(CSR) |

|

SRG

|

|

|

SRN

|

|

SRW

|

|

| Full Ball Guide | |||

| Apart from the Full Ball type guides mentioned above along with their Caged Ball equivalents, following are the other unique models created by THK | |||

|

RSR

RSRW RSH RSHZ |

|

HR

|

|

|

GSR

|

|

GSRR

|

|

|

HCR

|

|

HMG

|

|

|

NSR-TBC

|

|

JR

|

|

|

MX

|

|

M1

M2 |

|

|

Cross Roller Guide

|

|||

|

VR

|

|

VB

|

|

Â

Â

Product & Technology News

An industry wise glimpse at the array of applications where THK’s LM Guide is used.

| Machine Tools (SHS,SSR,SNR,SNS,SRG,HSR,NR,VR)

|

Medical

|

| Industrial Robots (HR,GSR,HSR,SR,SHS,SSR)

|

General Industrial Machinery (SSR,JR,SNR,SRN,SR,SNS,NRS)

|

| Precision Instruments (SCR,CSR,HMG,SHS,HSR)

|

Semiconductor and LCD manufacturing (RSR,SRS,MX,RSH,HRW,SHW,HSR)

|

| ElectronicDevices (RSR,SRS,MX,RSH,HR)

|

Transportsystems (VR,VB,SR,SSR,HSR,SHS)

|

|

Construction (SCR,CSR,MX,JR,NR,SNR,SNS)

|

Other Manufacturing Industries (HR,GSR,HSR,SHS,SR,SSR)

|

Products from Amcats Private Limited

Clamping & Braking Elements For Linear Guides

Products from MACHINE TOOLS, POWER & HAND TOOLS Category

Versatile Machining Capability Through Ram Type Milling & Grinding Heads